Lens Refurbishing

Dec 13, 2019 20:06:24 #

dsmeltz wrote:

Canon:

"Canon technicians perform comprehensive quality assurance inspections, replacing any needed parts with genuine Canon equipment. Plus, all refurbished products are...

You can't do these things without testing them to make sure they are met.

"Canon technicians perform comprehensive quality assurance inspections, replacing any needed parts with genuine Canon equipment. Plus, all refurbished products are...

You can't do these things without testing them to make sure they are met.

But there is no reason to believe that the testing of a refurb is any more comprehensive than a new lens. Speaking as the current quality manager for a small aerospace company, My guess (and it is only that) is that Canon tests every single lens that it sells since it is a complex assembly, and I would bet it is an automated process and errors are flagged. I would further bet that when a lens is returned, it is put through the same testing, and that any errors are detected and corrected and that it is retested by the same process until it passes or is permanently failed. Companies that sell thousands of the same assemblies don’t hand test, it’s not cost effective - the final QA is automated (and very sophisticated). Every manufacturer I know uses automated testing for complex assemblies. The only parts that are subjected to sampled testing are typically component piece parts, not assemblies. As an example, resistors, transistors and capacitors are sampled, but the assembled PC board is 100% tested by automatic testing systems. We sample QA incoming piece parts (such as screws), but 100% test the final product.

Dec 13, 2019 23:02:30 #

I read in a Nikon blurb that one type of Nikon refurbs were those cameras that failed the final QA inspection. They send that item back to determine the problem which is then repaired but cannot be sold as "New" so it is classified as "Refurbished" and can be sold.

Hawkowl and SuperflyTNT, try meatloaf, cold or warmed, in a sandwich with peanut butter and sliced gherkin pickles. Goes great with a cold Dr. Pepper.

Hawkowl and SuperflyTNT, try meatloaf, cold or warmed, in a sandwich with peanut butter and sliced gherkin pickles. Goes great with a cold Dr. Pepper.

Dec 13, 2019 23:05:53 #

Silverrails wrote:

I just bought a "Refurbished" Nikon Lens... (show quote)

Refurbished: someone looked at it and decided it looked good enough to sell with a short warranty.

Dec 13, 2019 23:27:34 #

trapper1 wrote:

I read in a Nikon blurb that one type of Nikon refurbs were those cameras that failed the final QA inspection. They send that item back to determine the problem which is then repaired but cannot be sold as "New" so it is classified as "Refurbished" and can be sold.

Hawkowl and SuperflyTNT, try meatloaf, cold or warmed, in a sandwich with peanut butter and sliced gherkin pickles. Goes great with a cold Dr. Pepper.

Hawkowl and SuperflyTNT, try meatloaf, cold or warmed, in a sandwich with peanut butter and sliced gherkin pickles. Goes great with a cold Dr. Pepper.

I don't know but if the camera doesn't leave the factory yet it's still can be sold as new in my opinion.

Dec 13, 2019 23:52:42 #

trapper1 wrote:

I read in a Nikon blurb that one type of Nikon refurbs were those cameras that failed the final QA inspection. They send that item back to determine the problem which is then repaired but cannot be sold as "New" so it is classified as "Refurbished" and can be sold.

Hawkowl and SuperflyTNT, try meatloaf, cold or warmed, in a sandwich with peanut butter and sliced gherkin pickles. Goes great with a cold Dr. Pepper.

Hawkowl and SuperflyTNT, try meatloaf, cold or warmed, in a sandwich with peanut butter and sliced gherkin pickles. Goes great with a cold Dr. Pepper.

Well, I do love pickles...and peanut butter goes with everything.

Dec 14, 2019 00:35:22 #

Dean37

Loc: Fresno, CA

I worked in Quality Assurance for nearly 40 years, and the comments below reflect what I know about the subject under discussion.

Most companies use sampling plans for items they sell, in order to keep the costs to the customer at an acceptable level. The plan might call for 1 item out of 100 to be inspected, or it might call for 10 items out of 100 to be inspected. The rates of inspection get adjusted up and down automatically with the rise or drop in failures. There is usually a series of tests the inspected item is subjected to, which should be 100% of its functions.

"Refurbished" items in most companies are subjected to testing 100% of the functions. Items that fail these tests then are generally scrapped. Theoretically the items that are sold as "Refurbished" are less likely to fail in use by the buyer than a new one as the new one likely has never been tested.

The companies need to keep the inspection costs to a minimum in order to keep the cost of the items they sell to a level that will keep buyers buying them, and if every item was inspected, they would put themselves out of business.

Most companies use sampling plans for items they sell, in order to keep the costs to the customer at an acceptable level. The plan might call for 1 item out of 100 to be inspected, or it might call for 10 items out of 100 to be inspected. The rates of inspection get adjusted up and down automatically with the rise or drop in failures. There is usually a series of tests the inspected item is subjected to, which should be 100% of its functions.

"Refurbished" items in most companies are subjected to testing 100% of the functions. Items that fail these tests then are generally scrapped. Theoretically the items that are sold as "Refurbished" are less likely to fail in use by the buyer than a new one as the new one likely has never been tested.

The companies need to keep the inspection costs to a minimum in order to keep the cost of the items they sell to a level that will keep buyers buying them, and if every item was inspected, they would put themselves out of business.

Dec 14, 2019 08:34:16 #

Dean37 wrote:

I worked in Quality Assurance for nearly 40 years,... (show quote)

Dean, i am just wondering what sort of products your company(s) sold. My time in QA is MUCH shorter than yours, but I did spend many years in design and > a dozen years in test equipment sales, so I saw almost every type of manufacturing, and almost every assembled item I saw manufactured was 100% final tested for functionality. That included everything from automobile CV Joints/half shafts to electric power tools to fuel injection pumps to PC boards to circuit breakers to dvd players. Some of those items sold in the $20 range (inexpensive Black and Decker power tools), but were 100% final tested, and almost always with automated test systems. I do completely agree that piece parts are generally sampled (I’m guessing inexpensive lens hoods are not for example). My company does purchase HW and CNC machined SS and aluminum parts, and we do sample those in incoming QA per mil spec sampling %., but the final assembled parts (that sell in the $50-$150 range) are 100% final inspected. I would guess that cameras and all but the cheapest lenses are 100% final inspected (probably by an automated process), but I could be mistaken.

Dec 14, 2019 13:35:22 #

The Canon tech that convinced me to buy factory refurbished stated to me that Canon manufacturing tests 1 in 10 randomly. That means that at a minimum 1 out of 10. At best it could be 2out of 2. Our company inspected every item 100%, which is highly unusual in our market. That was the reason why we could demand up to 10 times the price common in our industry.

WJH

WJH

Dec 14, 2019 15:00:54 #

williejoha wrote:

The Canon tech that convinced me to buy factory refurbished stated to me that Canon manufacturing tests 1 in 10 randomly. That means that at a minimum 1 out of 10. At best it could be 2out of 2. Our company inspected every item 100%, which is highly unusual in our market. That was the reason why we could demand up to 10 times the price common in our industry.

WJH

WJH

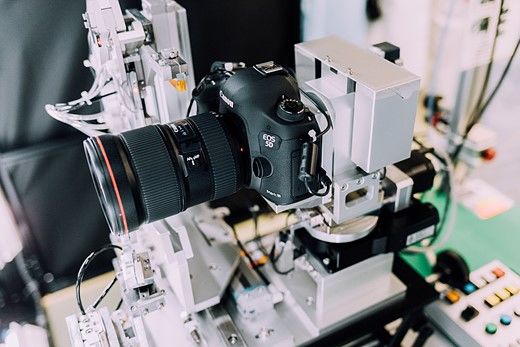

I wonder if that tech was referring to all Canon lenses and if he had ever actually visited the assembly line. According to an interview with the head of Canon’s L series factory, 100% of L series are tested: https://www.dpreview.com/interviews/4536277079/canon-lens-factory-interview

Here’s an image of the automated testing fixture:

Dec 14, 2019 15:08:10 #

I can believe that it would be true for their upper end bodies and lenses. It would make a lot of sense.

WJH

WJH

Dec 14, 2019 15:36:31 #

Dean37

Loc: Fresno, CA

TriX, our finished product did get basic testing and had to run a minimum number of miles and the customer performed their minimum testing, before acceptance.

Our sampling plans met Government requirements for parts being inspected prior to final assembly into our military vehicles. As I stated above, we did a basic minimum test.

I did not talk about the finished product before and apologize for the mistake, on my part.

Although I was involved in the final product tests, and Government acceptance at delivery, that was not in my thoughts at the time.

Most of the final product testing I was involved in was the embedded software which was tested in detail on a first article, though specific minimum function tests were performed with the software, as requested by the Government, on each vehicle.

Our sampling plans met Government requirements for parts being inspected prior to final assembly into our military vehicles. As I stated above, we did a basic minimum test.

I did not talk about the finished product before and apologize for the mistake, on my part.

Although I was involved in the final product tests, and Government acceptance at delivery, that was not in my thoughts at the time.

Most of the final product testing I was involved in was the embedded software which was tested in detail on a first article, though specific minimum function tests were performed with the software, as requested by the Government, on each vehicle.

Dec 14, 2019 15:48:43 #

Dean37 wrote:

TriX, our finished product did get basic testing a... (show quote)

Thanks Dean. We sample incoming parts per Mil STD 105E. Although that standard has been superseded, many of our suppliers and DOD customers still use it. What do you use?

Cheers

Dec 16, 2019 10:25:03 #

TriX wrote:

But there is no reason to believe that the testing... (show quote)

Quality control in aerospace is different than in consumer manufacturing by the nature of the results of failure of the products. Your experience really does not translate to general manufacturing of consumer products.

Dec 16, 2019 11:45:35 #

dsmeltz wrote:

Quality control in aerospace is different than in consumer manufacturing by the nature of the results of failure of the products. Your experience really does not translate to general manufacturing of consumer products.

Wouldn't it be wonderful if there was a Federal Camera Authority that set standards for our toys?

Nevermind. They would just let the companies do it, like hte Boeing 737.

Dec 16, 2019 13:42:08 #

dsmeltz wrote:

Quality control in aerospace is different than in consumer manufacturing by the nature of the results of failure of the products. Your experience really does not translate to general manufacturing of consumer products.

Well, I also referenced $20 electric drills, DVD players that sell for less than $100, circuit breakers that sell for ~$15 and PC boards that probably sell for $20, all of which are final tested 100%, so why would you assume that camera lenses that sell for hundreds of dollars are not 100% final tested (using automated testing)?

If you want to reply, then register here. Registration is free and your account is created instantly, so you can post right away.