people ask me "what is a toolmaker?"

Nov 2, 2014 17:00:54 #

A toolmaker is a skilled worker who produces and maintains precision tools used in the production of metal, plastic and other materials of all shapes and sizes. The work of a toolmaker involves interpreting drawings and technical data to machine and assemble with great accuracy jigs, fixtures, moulding tools, dies and punches. Care and attention to detail and high precision are the hallmark of toolmaking. The use of lathe, milling machine, surface grinders, drilling and spark erosion equipment are the key skills as are the use of precision, marking out and measuring tools. Modern technologies such as wire erosion, computer aided design (CAD) Computer aided manufacture (CAM) and computer numeral control (CNC) machining have become an integral part of the work of the toolmaker.

Nov 2, 2014 17:15:14 #

And tell them it is an earned and respected trade with

many years at college as is

a Fitter and Machinist, previously a Fitter and Turner.

Not someone who walks out of high school into a

job changing oil in a car and call themselves an

engineer.

Can you tell that I'm a Fitter and Machinist ??

many years at college as is

a Fitter and Machinist, previously a Fitter and Turner.

Not someone who walks out of high school into a

job changing oil in a car and call themselves an

engineer.

Can you tell that I'm a Fitter and Machinist ??

Nov 2, 2014 17:20:01 #

pageva wrote:

A toolmaker is a skilled worker who produces and m... (show quote)

Having designed tools, fixtures, and gages for a number of years, the images capture the tool maker perfectly. The first, the look of bewilderment while trying to decipher the tool designer's scribbles on a piece of paper. The second, catching a few ZZs while the computer controlled machine makes the part.

Just kidding, I've held tool and die machinists in the highest regard, as they make what they do from minimal information drawings. They also make features within unreal tolerances.

Nothing like having a leader point to a hole with a callout of .2500 +.0002/-.0000 DIA. The associated pin that is to slide in that hole is called out as MATE WITH .2500 DIA SFNS. The final product works perfectly.

--Bob

Nov 2, 2014 17:38:43 #

thanks, I had to work 10,000 hours as an apprentice to become a Journeyman toolmaker. Then along came the computer numerical controlled (CNC) and the learning begins again.

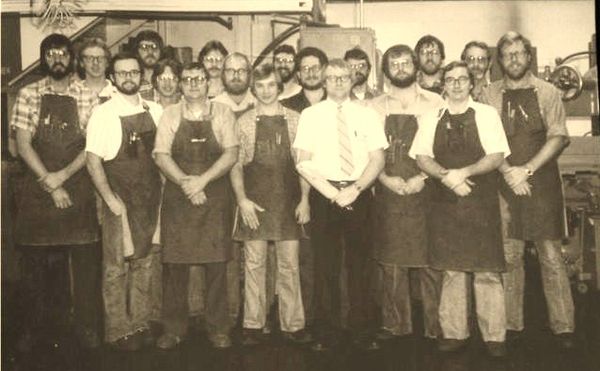

this was when I started in 1979, also shot and developed this photo myself

(Download)

my first completed job, winding chucks for armatures

(Download)

Nov 2, 2014 17:41:38 #

Nov 2, 2014 18:14:09 #

And as far as I am concerned, a good engineers best friend. The Tool and Die Machinists/Makers I have had the privilege to work with saved my ass many of times. Both with their knowledge and craftsmanship.

Nov 2, 2014 20:59:28 #

I make the odd tool as I need it. Compound curved bottom planes to make carved top & bottom instruments. ( instruments are tools for me as well.)

My most useful is my Scandinavian workbench. A design 100's of years old. The dog holes close on one another, allowing hands free work.

My most useful is my Scandinavian workbench. A design 100's of years old. The dog holes close on one another, allowing hands free work.

Nov 3, 2014 06:52:34 #

I got pulled of my 'Craft' apprenticeship and upgraded to 'Technical' apprenticeship. But the time I spent in the Toolroom served me well when I had to design the jigs!

Nov 3, 2014 07:21:54 #

Unfortunately in our country a growing number of people don't know or care where precision tooling is made or repaired. Management always wants a 1 year payback so the overseas parts are of course cheaper, even when they are made to a lower tolerance/ quality makes no difference. I hope the day comes when american management structure is taught to look generations ahead for what their decisions cost.

Nov 3, 2014 09:04:53 #

JennT

Loc: South Central PA

I know a tool maker----he custom designs, make tools for surgeons---a graduate of Rhode Island school of Design.

Nov 3, 2014 09:10:36 #

JennT wrote:

I know a tool maker----he custom designs, make tools for surgeons---a graduate of Rhode Island school of Design.

I would be very keen to see his work! Any links?

Nov 3, 2014 09:25:46 #

RichieC

Loc: Adirondacks

My dad was a journeyman master machinist, "Tool & Die maker" I know of one die he made, to produce boot trees on a press, that has been used continuously every week or so since the 50's. At his funeral, the companies main foreman told me that he shows it to just about everybody who has any interest in such things, because of its simplicity and efficiency in doing it all in one step. That he never fails to go and watch it run when they have an order. That was just one of many... he could fix anything, rebuild engines, refinish and rebuild a wood sailboat, built his own house, said the only thing he didn't do was dig the hole.

He walked the length of Italy in WW2, but never went to college...

He walked the length of Italy in WW2, but never went to college...

Nov 3, 2014 10:04:28 #

Started apprenticeship in 1966 and retired after 43 very rewarding years. Became supervisor in the TR In 1976 and managed 2 shops until my retirement. But to answer the question " what is a toolmaker". Well my take is he is a jack of all trades and master of many, he is a machinist, a problem solver, a inventor and a person that engineers like to have many times solve their problems and get little credit for it.

Nov 3, 2014 10:21:00 #

Nov 3, 2014 11:18:25 #

wbym300 wrote:

Unfortunately in our country a growing number of people don't know or care where precision tooling is made or repaired. Management always wants a 1 year payback so the overseas parts are of course cheaper, even when they are made to a lower tolerance/ quality makes no difference. I hope the day comes when american management structure is taught to look generations ahead for what their decisions cost.

I am an amateur woodworker, with some nice machines in my shop. A few years ago, bought a Chinese made 8" jointer. Table was never truly flat, and to adjust it parallel I had to make my own tool. Every time I tried to adjust the blades, you'd set the blade height just right, but when you went to tighten them down, your adjustment would shift.

I finally got so frustrated, I ordered a helical cutting head with rotatable carbide insert cutters. No height adjustment, so that issue solved.

Since I had to take the damn thing apart to replace the cutters, I figured I'd find a machine shop in Albuquerque to grind the infeed and outside tables flat--The infeed table, 8" by 42", was dished .006" in the center, down most of the length of it. No one in town said they could work on it, so I hand sanded it with a 9x12x2.5 inch granite block (VERY flat!!)with 36 grit self adhesive sandpaper, from a floor sanding disk, adhered to it.

After several days of that, It got very close to flat, and a few lighter grits later I reassembled it, with some judiciously applied grease. It now works like it should have worked from the git go.

Bottom line, I appreciate what you guys do, and won't buy anymore cheaply made machines--unless I know up front what it takes to rebuild them.

If you want to reply, then register here. Registration is free and your account is created instantly, so you can post right away.