Gold Plated - Something of Interest to Motor Mechanics and Diesel Fitters

Jan 31, 2023 04:13:09 #

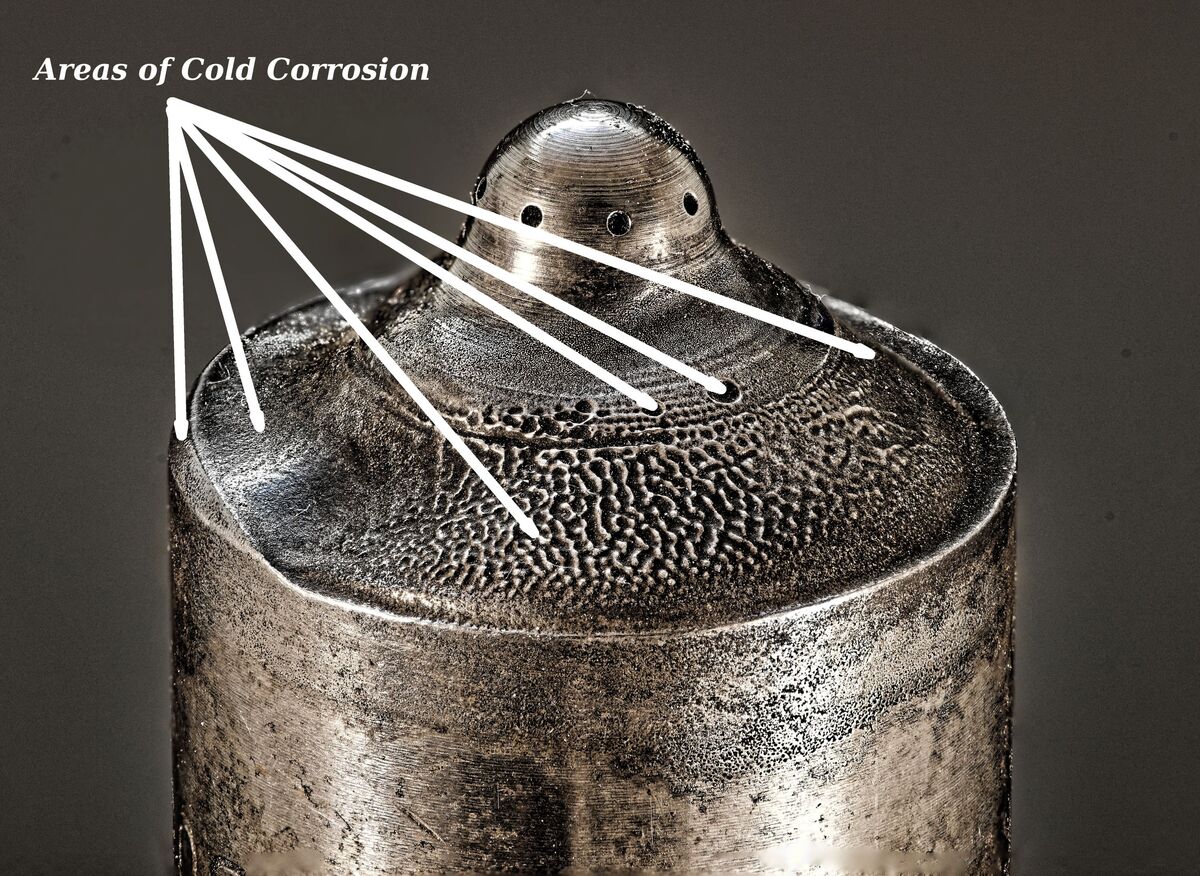

Cold corrosion occurs in diesel engines when products of combustion - sulphur oxides and water vapour combine to form sulphuric acid which condense on cooler surfaces inside the combustion space. Cold corrosion is more likely to occur when engines are running at low load and when running temperatures are lower than optimum.

The following is drawn from my experiences involved in the maintenance and operation of a power station in Central Australia for almost 40 years.

The attached images are of injector nozzles from a 5.6MW (electrical output) V16 cylinder Mirrlees KV16 P Major engine. The engine started its life in 1973 as a conventional four stroke diesel engine driving a salient pole alternator at 500 rpm producing electricity at 11,000 volts and 50 hertz.

In 1983 after natural gas became available the engines in the power station were converted to duel fuel. During dual fuel operation a metered quantity of gas (determined by the load on the engine) is admitted to the cylinders during the air intake stroke. The resulting air / gas mixture is compressed and a small amount of diesel fuel is injected at the appropriate time to start the combustion process.

Cold corrosion of injector nozzles became evident in the early days of duel fuel operation. One solution offered by the engine manufacturer (Mirrlees Blackstone in the United Kingdom) was to fit gold plated injector nozzles. Whilst the gold plated nozzles did last longer than the non plated ones, they were also three times the price of non plated nozzles but unfortunately they did not last three times longer.

One of the contributing factors to the occurrence of cold corrosion of the injector nozzles was that they needed to be water cooled for duel fuel operation. During normal diesel operation there is sufficient fuel passing through the injector nozzle to prevent it from overheating but less than 5% of that volume of fuel passes through the injector nozzle during dual fuel operation so water cooling of the nozzle then becomes necessary.

Over time, increased experience with dual fuel operation and improvements with engine tuning led to a reduction of the severity of injector nozzle cold corrosion by reducing running time on diesel fuel only and by maintaining higher loads when running in dual fuel mode.

The following is drawn from my experiences involved in the maintenance and operation of a power station in Central Australia for almost 40 years.

The attached images are of injector nozzles from a 5.6MW (electrical output) V16 cylinder Mirrlees KV16 P Major engine. The engine started its life in 1973 as a conventional four stroke diesel engine driving a salient pole alternator at 500 rpm producing electricity at 11,000 volts and 50 hertz.

In 1983 after natural gas became available the engines in the power station were converted to duel fuel. During dual fuel operation a metered quantity of gas (determined by the load on the engine) is admitted to the cylinders during the air intake stroke. The resulting air / gas mixture is compressed and a small amount of diesel fuel is injected at the appropriate time to start the combustion process.

Cold corrosion of injector nozzles became evident in the early days of duel fuel operation. One solution offered by the engine manufacturer (Mirrlees Blackstone in the United Kingdom) was to fit gold plated injector nozzles. Whilst the gold plated nozzles did last longer than the non plated ones, they were also three times the price of non plated nozzles but unfortunately they did not last three times longer.

One of the contributing factors to the occurrence of cold corrosion of the injector nozzles was that they needed to be water cooled for duel fuel operation. During normal diesel operation there is sufficient fuel passing through the injector nozzle to prevent it from overheating but less than 5% of that volume of fuel passes through the injector nozzle during dual fuel operation so water cooling of the nozzle then becomes necessary.

Over time, increased experience with dual fuel operation and improvements with engine tuning led to a reduction of the severity of injector nozzle cold corrosion by reducing running time on diesel fuel only and by maintaining higher loads when running in dual fuel mode.

Note the gold plated injector nozzle on the left and the non plated nozzle on the right.

(Download)

Note the extent of cold corrosion damage to the unplated injector nozzle on the right after about 5,000 hours of operation Compared to 8,000 hours for the gold plated nozzle on the left.

(Download)

Close up view of cold corrosion damage to the unplated injector nozzle.

(Download)

The engine that the above injector nozzles were removed from - a 5.6MW (electrical) V16 cylinder Mirrlees KV16 P Major diesel engine made by Mirrlees Blackstone in the UK in 1972, converted to dual fuel in 1983..

(Download)

Jan 31, 2023 04:33:21 #

Jan 31, 2023 04:41:30 #

Jan 31, 2023 05:05:00 #

A well-done photo of a large power generator. Big machines attract my eye. Thanks for sharing.

Thorny Devil wrote:

Cold corrosion occurs in diesel engines when produ... (show quote)

Jan 31, 2023 05:14:19 #

Thorny Devil wrote:

Cold corrosion occurs in diesel engines when produ... (show quote)

Great set of images!!!

Haven't they eliminate sulphur from diesel fuel down there ?

I am assuming these engines use the same type of diesel fuel as they use in trains and some marine applications.

Jan 31, 2023 05:41:56 #

Jan 31, 2023 05:47:45 #

Fascinating post. I am just trying to figure out how I can get that V16 into my car!!!

Jan 31, 2023 06:04:44 #

Some may ask, "who cares about all this corrosion stuff?" Fitting question... and the reply is those of us who have lived with engines since teens especially we who may have owned GM's failed conversion of a gasoline engine into a diesel in the early 80's. Or those of us who saw the love affair between the diesel submarine engine and the caring mechanic in the movie "Das Boot".

I personally find the failure analysis to be intriguing and informative... during my work at Firestone Fibers I did tire yarn failure analysis utilizing Scanning Electron Microscopy. Thank you for sharing your work Thorny Devil

I personally find the failure analysis to be intriguing and informative... during my work at Firestone Fibers I did tire yarn failure analysis utilizing Scanning Electron Microscopy. Thank you for sharing your work Thorny Devil

Jan 31, 2023 06:06:23 #

Jan 31, 2023 07:11:57 #

Thorny Devil wrote:

Cold corrosion occurs in diesel engines when produ... (show quote)

Thanks for a very interesting post! I don't know a lot about engines but would Titanium be suitable for these injectors? Also, the gold-plated ones may not have given three times the life but when you factor in less downtime and maintenance costs, they may have been worth the money.

Jan 31, 2023 08:11:22 #

Blair Shaw Jr wrote:

Fascinating post....thank you.

Thanks for the feedback Blair.

Jan 31, 2023 08:12:06 #

Architect1776 wrote:

Thanks for looking Architect.

Jan 31, 2023 08:12:54 #

anotherview wrote:

A well-done photo of a large power generator. Big machines attract my eye. Thanks for sharing.

Thanks for your feedback anotherview.

Jan 31, 2023 08:50:00 #

Manglesphoto wrote:

Great set of images!!!

Haven't they eliminate sulphur from diesel fuel down there ?

I am assuming these engines use the same type of diesel fuel as they use in trains and some marine applications.

Haven't they eliminate sulphur from diesel fuel down there ?

I am assuming these engines use the same type of diesel fuel as they use in trains and some marine applications.

Thanks for you encouraging feedback Mangles.

Low sulphur diesel fuel was introduced to the power station that I worked at about 15 or 20 years ago by which time the rate of cold corrosion had slowed compared to what was being experienced in the earlier days of dual fuel operation. It should also be noted that the engines that I referred to were 1970's technology and are no longer in regular use since a new power station with larger plant and the latest technology was commissioned a couple of years before I retired in 2013. Regards, Richard.

Jan 31, 2023 08:50:41 #

llamb wrote:

Great post. Thanks.

~Lee

~Lee

Thanks for the encouraging feedback llamb.

If you want to reply, then register here. Registration is free and your account is created instantly, so you can post right away.