Trying to build a miter saw sled

Nov 13, 2023 15:50:00 #

I've seen a past post from Jerry about building a cross cut sled for his table saw. Here is my experience for what it's worth. I've been trying to put one together to make picture frames. Watched a bunch of YouTube videos, seems simple enough, especially if you have fully equipped wood shop! Which I don't. Anyway, ordered a pair of "sliders" from amazon to fit the slots in my saw where the miter gauge would go. Had to do some sanding to make them easily slide without binding up, no problem they slide easy enough and don't wobble. Next step is to put together the base and fasten everything together. The issue is when I fasten the sliders to the bottom of my plywood and try it out on the saw about half way the sliders bind up. I've tried several different approaches, with the same result. My only conclusion is the slots are far enough out of being parallel that it is causing the binding problem. Of course my saw isn't a high dollar, precision tool that is being used in the videos. So I removed one slider for the time being. I'll follow up with the results after I get things together and have attempted to make a couple of frames. Keep Clicking!

Nov 13, 2023 18:25:02 #

GreenReaper wrote:

I've seen a past post from Jerry about building a ... (show quote)

Make sure the blade is parallel with the ways in the top. Most tops have some adjustment. Any pics?

Nov 13, 2023 21:42:05 #

Does your table saw have a cast iron top and are both mitre slots in the same section of the top? It’s possible they aren’t parallel, but more likely your slides aren’t. They only have to be a few thousands out of parallel end to end to bind. There are lots of clever ways to get them right, but when I built my sled, I mounted one slide making sure it was EXACTLY perpendicular to the surface the material being cut rests against. Then I placed a strip of double sided tape on the bottom of the sled where the other slide should go. I then place the 2nd slide in its slot in approximately the correct location, and with the sled’s other slide in its slot, I ease the sled down on to the 2nd slide and press it firmly into the tape. I then turn the sled over and screw the 2nd slide in place. The slides I use also have adjusting tabs to set the clearence in the slots

Nov 14, 2023 07:33:07 #

My suggestion: make your slides, place them in the table saw slots, apply double sided tape to the slides then carefully place a scrap mdf board on top. See if this slides properly, I expect it should. Make sure the slides project above the table saw top. If all goes well repeat with your real sled, screw down the slides then hand plane them down till the sled rides on the saw top.

Nov 15, 2023 15:39:21 #

Nov 15, 2023 15:46:39 #

Actually it's heavy duty aluminum. It's a Kobalt product purchased from Lowe's. It seems to be built different than the ordinary portable table saw. I won't go into all the differences here, but the main reason I bought this particular brand is the slots seemed to be a little tighter than the others that I looked at. I've tried the double sided tape and the super glue thing to no avail. Right now I've removed one runner, I have not had the time to try out the accuracy of the cuts, when I do I'll post the results. Thanks for all the info and ideas.

Nov 15, 2023 17:57:26 #

Do you have an accurate way to measure the parallelism of th slots?just a piece of paper, carefully marked may be adequate. Have you tried sliding the slides the full length of the slot to make sure they slide smoothly and there are no irregularities in the slot?

Nov 16, 2023 14:25:38 #

The slides will move the entire length of the slot smoothly with, no binding, until they are attached to the base. Attached to the base the entire setup will move about halfway on the out feed then bind up. Still working on alternative solutions. Thanks to all for the help and advice.

Nov 28, 2023 11:08:32 #

Just a quick follow up, it turns out my slots for the miter gauge are not exactly parallel! with my somewhat crude way of measuring, or checking for them being parallel, they seem to be out just enough to cause a problem. I'd guesstimate less than 1/16th". Like I said a guesstimate. So I have moved onto using my miter saw to try and cut frames. I've used a triangle to set the 45 deg as opposed to using the detent, and Ive got a board setup with whatever else I need. So far so good. Plan on trying it out today.

Nov 28, 2023 11:15:50 #

GreenReaper wrote:

Just a quick follow up, it turns out my slots for ... (show quote)

In my opinion, the Mitre saw is the best tool to cut picture frames anyway.

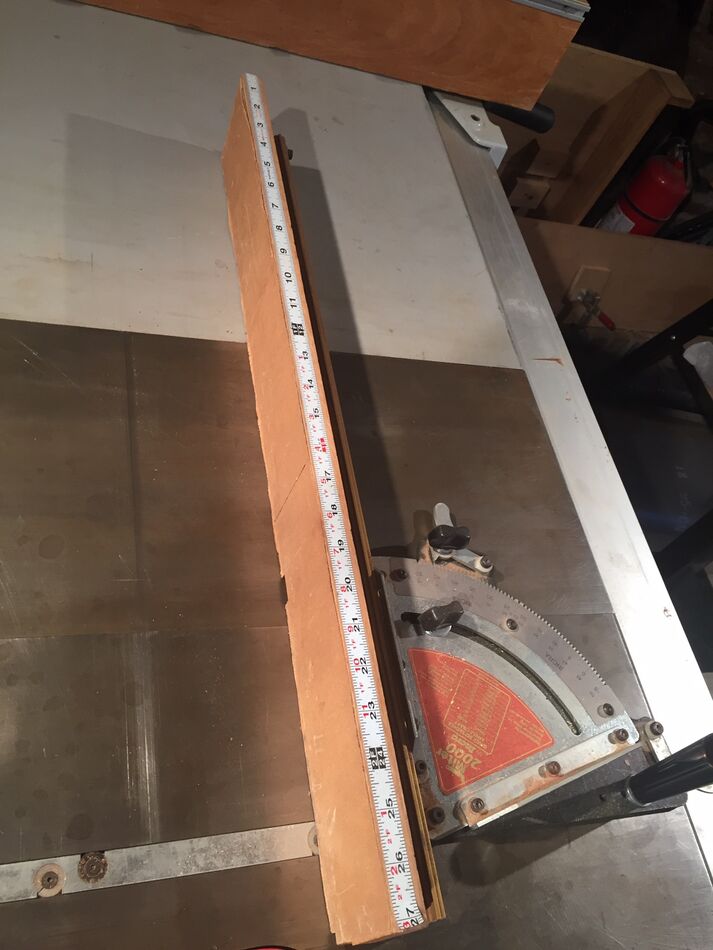

BTW, while the sled is great for cutting long pieces, a good quality mitre such as those made by Incra and use only one slot in the table will work fine for picture frame cuts - just screw a wooden fence onto the mitre garage to provide support for longer pieces and then calibrate the mitre (if needed). Here’s an image of mine. The fence is just a scarp piece 3” wide and 27” long - plenty long enough to support a picture frame side (but I’d still use the mitre saw instead)

If you want to reply, then register here. Registration is free and your account is created instantly, so you can post right away.