An industrial wasteland: What was and what's no longer there...

Apr 28, 2023 20:17:23 #

This is going to be a series of posts covering places I've seen, and one of them, where I once worked, which were part of a thriving commercial operation at one time but which has since all but disappeared.

I'll start with the company where I co-opted while I was in engineering school and where I went to work after I graduated. The name of the company was Baker Perkins Inc, located in Saginaw, Michigan. It was owned by a holding company, Baker Perkins Ltd, out of Peterborough, England. We designed and manufactured chemical and food machinery. I worked in the Food Machinery division, which manufactured equipment for larger commercial bakeries, mostly pan breads, which include hamburger and hot dog rolls. We also sold large cake and pie lines as well as the occasional cookie line. Now this were very large production facilities, bread lines that produced up to 200 loaves/minute. We supplied the machinery for a bakery in New Jersey that had only one customer, McDonald's, and it produced 40,000 buns (Bic Mac/Quarter Pounder) per hour.

Anyway, I worked there from 1966 until 1980, first as a draftsman during summers between classes, and then as a machine designer after I graduated in 1971. When I left there, and moved to California, I was a Project Engineer in the R&D department. Note that I did leave with a fully-vested pension, which I started to collect when I turned 65. It doesn't pay much, but I can usually count on it covering our electric bill each month.

A couple of years after I left, they moved the Food Machinery division from Saginaw to Goldsboro, North Carolina, a 'right-to-work-for-less' state. About 15 years later, while they left the factory operation in Goldsboro, they moved engineering back to Michigan and merged it with another one of BP Ltd's companies in Grand Rapids. The Chemical operation remained at the Saginaw location but was spun-off a few years later and while they kept the R&D office there, they moved manufacturing to another location.

I'll start with the company where I co-opted while I was in engineering school and where I went to work after I graduated. The name of the company was Baker Perkins Inc, located in Saginaw, Michigan. It was owned by a holding company, Baker Perkins Ltd, out of Peterborough, England. We designed and manufactured chemical and food machinery. I worked in the Food Machinery division, which manufactured equipment for larger commercial bakeries, mostly pan breads, which include hamburger and hot dog rolls. We also sold large cake and pie lines as well as the occasional cookie line. Now this were very large production facilities, bread lines that produced up to 200 loaves/minute. We supplied the machinery for a bakery in New Jersey that had only one customer, McDonald's, and it produced 40,000 buns (Bic Mac/Quarter Pounder) per hour.

Anyway, I worked there from 1966 until 1980, first as a draftsman during summers between classes, and then as a machine designer after I graduated in 1971. When I left there, and moved to California, I was a Project Engineer in the R&D department. Note that I did leave with a fully-vested pension, which I started to collect when I turned 65. It doesn't pay much, but I can usually count on it covering our electric bill each month.

A couple of years after I left, they moved the Food Machinery division from Saginaw to Goldsboro, North Carolina, a 'right-to-work-for-less' state. About 15 years later, while they left the factory operation in Goldsboro, they moved engineering back to Michigan and merged it with another one of BP Ltd's companies in Grand Rapids. The Chemical operation remained at the Saginaw location but was spun-off a few years later and while they kept the R&D office there, they moved manufacturing to another location.

This is what our facility looked like at it's height - June 1977 - Minolta SRT-101, 135mm

This is what the outside of the main office building looked like. This was taken after most of the operation had already moved - April 2014 - Sony A65, 10-24mm

This is what our design and drawing office looked like (these photos were taken one Saturday when a few of us were working some overtime on a rush project) - August 1970 - Minolta SRT-101, 135mm

Another shot taken on that overtime weekend - August 1970 - Minolta SRT-101, 135mm

And this is what that office looked like when I stop once after they had closed and had abandoned most of the building - April 2014 - Sony A65, 10-24mm

And this is what part of property looked like the last time I stopped by the place, after they had demolished most of the old factory buildings - August 2017 - Sony a6000, 16-50mm

Apr 28, 2023 20:45:09 #

Interesting. Sad to see the end of useful life for a building which at one point had purposeful activity producing both end products and livelihoods for many people. What stories occurred therein.

Apr 28, 2023 20:57:11 #

Apr 28, 2023 21:57:38 #

Apr 28, 2023 23:04:44 #

Flying Three wrote:

.Great story, but it makes me sad. . . .

My thoughts also...I think back on all the changes I went through over 60+ years. The vibrancy & bustling activities, 1000+ workers all intertwining their lives & hopes & goals, helping one another for the common good & achieving personal goals. The problems solved, the sacrifices made to "finish" the project. The overtime hours, the brainpower expended... sometimes even successfully! ☺The parties & awards & families getting to come together...so much time & effort & thought, good & bad , but like putting your finger in the still waters of a lake and then pulling it out...soon no visible trace will be left.

It still exists! But only in the mind of the old gentleman sitting in the sun & quietly reminiscing on things he has done that no longer matter, impossible demands met & exceeded, surprises no one expected, the kindness & generosity of people everywhere are amazing...and so is the flip side, the darker side but overall it was good. The skills & knowledge & experience of everyone involved were/are of so much value, the old man realizes even in this hi tech age you need someone who knows what to do when you flip the switch and there are no lights.

Apr 29, 2023 01:13:22 #

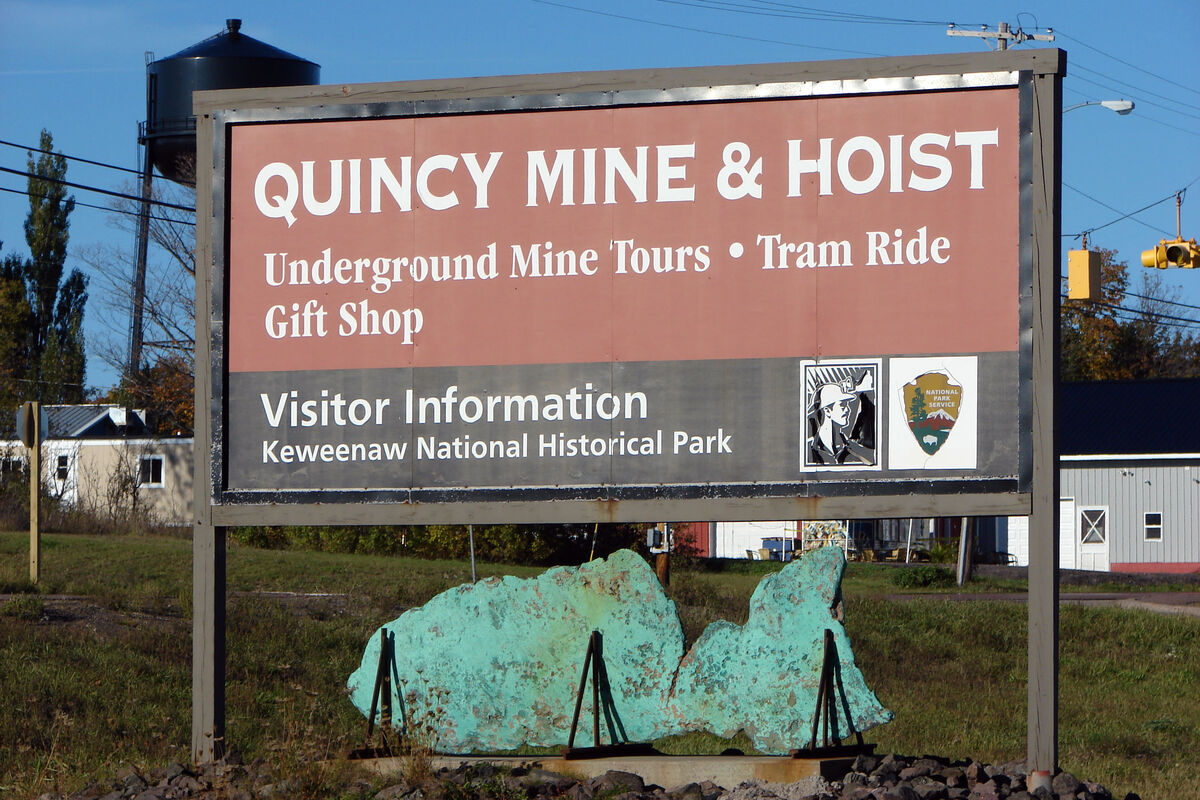

My next couple of posts deal with an industry which was responsible for my university even existing, mining. My alma mater, Michigan Technological University, in Houghton, located in Michigan's Upper Peninsula, was founded in 1885 as the Michigan School of Mines, established to train mining engineers, specifically for the Iron and Copper industries, as these were the two primary minerals being mined in that part of the state.

And one of the most famous of those mines was the Quincy Mine, in Hancock, just across the lake from Houghton. The mine was first opened in 1847 and was once the most productive Copper mine in North America. Note that the Copper mined in the UP of Michigan was pure Copper and did not require chemical processing but only mechanical, breaking it away from the the crystalline substrate that it was often found in, using large stamping mills. For nearly a century, Copper was being removed from the Quincy Mine, until 1945, when, with the end of WWII, the price of Copper dropped to the point where deep-shaft mining of Copper was no longer profitable. And deep-shaft mining is what the Quincy was famous for. At the time that the mine closed, the main shaft of Quincy #2 was over 9,000 feet long, the longest mine shaft in the world at the time. The main shaft was dug at a 55˚ angle to align with the strata of the deposits. This resulted in the end of the shaft being over 6,200 feet below ground.

Now there were other mining companies in the area, but the Quincy was the largest and most productive operation.

And one of the most famous of those mines was the Quincy Mine, in Hancock, just across the lake from Houghton. The mine was first opened in 1847 and was once the most productive Copper mine in North America. Note that the Copper mined in the UP of Michigan was pure Copper and did not require chemical processing but only mechanical, breaking it away from the the crystalline substrate that it was often found in, using large stamping mills. For nearly a century, Copper was being removed from the Quincy Mine, until 1945, when, with the end of WWII, the price of Copper dropped to the point where deep-shaft mining of Copper was no longer profitable. And deep-shaft mining is what the Quincy was famous for. At the time that the mine closed, the main shaft of Quincy #2 was over 9,000 feet long, the longest mine shaft in the world at the time. The main shaft was dug at a 55˚ angle to align with the strata of the deposits. This resulted in the end of the shaft being over 6,200 feet below ground.

Now there were other mining companies in the area, but the Quincy was the largest and most productive operation.

This is what the Quincy #2 shaft house looks like, the shape being determined by that 55˚ shaft angle - December 1970 - Minolta SRT-101, 58mm

The sign identifying that the Quincy Mine and the Hoist House are now part of the National Park System, and yes, that's an example of what the Copper looked like which was taken from the Quincy Mine - October 2010 - Sony DSC-H2

This is the hoist house which contained the machinery used to pull the ore cars up and down the main shaft of the Quincy Mine - August 1988 - Minolta XG-M, 35mm

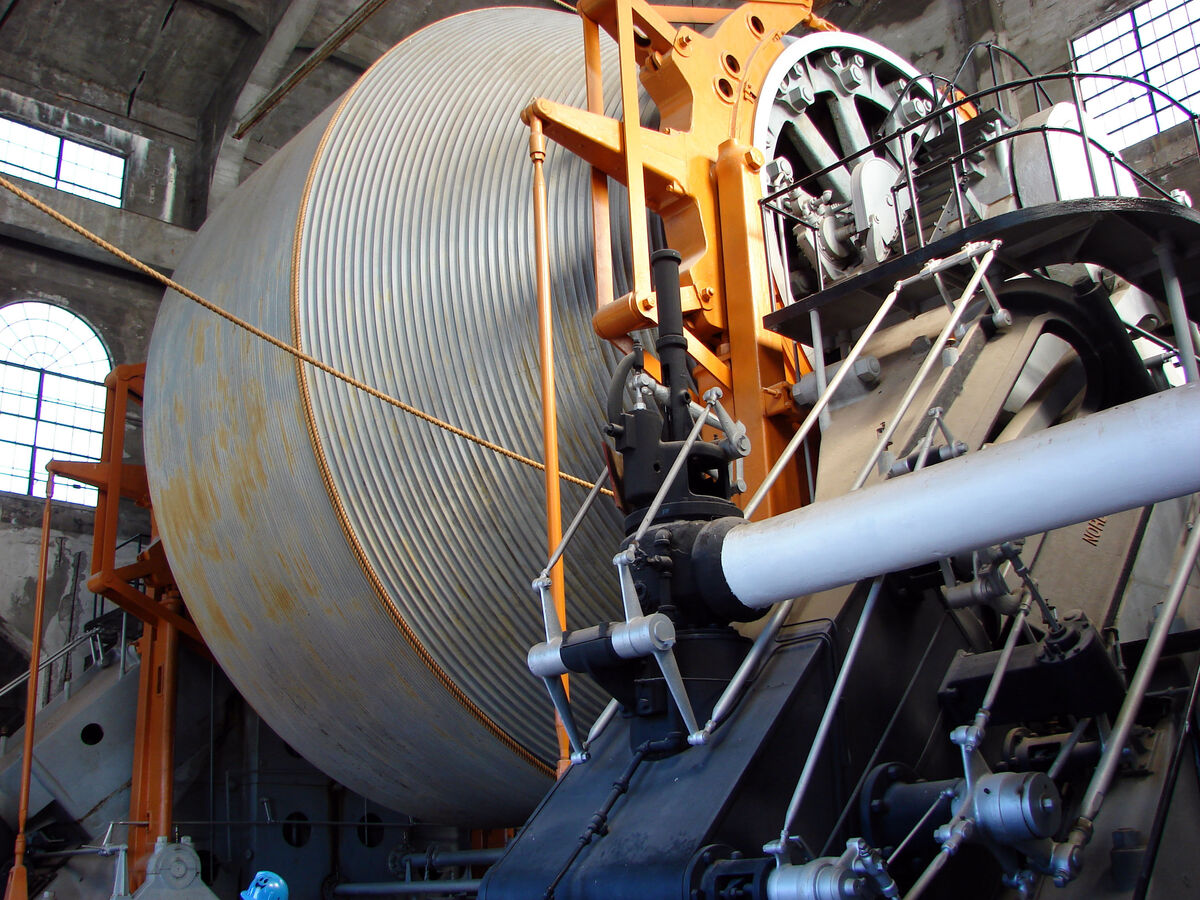

This is the steam-powered hoist which could hold nearly 11,000 feet of cable - October 2010 - Sony DSC-H2

Here are some of the other buildings on the site which the National Park Service is attempting retain in as good a condition as possible - April 2014 - Sony A65, 28-75mm

Another building on the site which has suffered a bit more wear and tear - July 2021 - Sony a6500, 18-135mm

The Quincy smelter where the final processing and casting of ingots was done, on Portage Lake, where ships were still loading ingots 20 years after the mine closed. It's currently being restored as a museum - July 2021 - Sony a6500, 18-135mm

A more recent photo of the shaft house of Quincy #2, showing the amount of repair and resoration that has taken place since the site was taken over my the National Park Service - October 2010 - Sony DSC-H2

Apr 29, 2023 01:53:52 #

This next post shows off some other places associated with the Copper mining industry in the Houghton/Hancock area, however, these are not as well maintained, yet they survive as a testament to the scope and significant role that Copper mining played in these communities for nearly a century.

This is all that remains of the Quincy reclamation sand mill in Mason, where they would reprocess the tailings from the stamping mills, extracting additional amounts of Copper ore - July 2021 - Sony a6500, 18-135mm

This is the smoke stack at the reclamation sand mill - July 2021 - Sony a6500, 18-135mm

And this is all that remains of the structure where the reprocessing machinery once operated - July 2021 - Sony a6500, 18-135mm

And this shows how Mother Nature has slowly been attempting to reclaim the area - July 2021 - Sony a6500, 18-135mm

This photo wasn't taken strictly for its artistic value but because it also seemed to be indicative of the old yet still solid construction of the facility, despite what Mother Nature was attempting to do - July 2021 - Sony a6500, 18-135mm

This is the Quincy dredge number two, used to collect the tailings for reprocessing. Note that this dredge has been there, just a bit more dilapidated, since before I started at the university, which was in 1965 - July 2021 - Sony a6500, 18-135mm

Now this was part of one of those stamping mills, in Hubbell, run by a different mining company, the Calumet & Hecla Mining Company, which was actually the last mining company operating in the area - July 2021 - Sony a6500, 18-135mm

Another shot of what remains of that same Calumet & Hecla stamping mill in Hubbell - July 2021 - Sony a6500, 18-135mm

Apr 29, 2023 02:48:32 #

OldCADuser,

Thanks for sharing your images, especially Quincy Mine, I was there in 2016 and have almost the same images as you have posted, very interesting place, did the mine tour and above ground...

Thanks for sharing your images, especially Quincy Mine, I was there in 2016 and have almost the same images as you have posted, very interesting place, did the mine tour and above ground...

Apr 29, 2023 07:25:31 #

Apr 29, 2023 09:20:48 #

Sad to see the decline in US manufacturing as much of it has been outsourced to other countries.

Apr 29, 2023 10:55:21 #

Busbum wrote:

OldCADuser,

Thanks for sharing your images, especially Quincy Mine, I was there in 2016 and have almost the same images as you have posted, very interesting place, did the mine tour and above ground...

Thanks for sharing your images, especially Quincy Mine, I was there in 2016 and have almost the same images as you have posted, very interesting place, did the mine tour and above ground...

Yes, I've done the mine tour as well. Perhaps I'll post some pictures of that as well.

Apr 29, 2023 11:13:08 #

azted

Loc: Las Vegas, NV.

Fascinating posts. This parallels the term "creative destruction" that exists due to time marching on. We have to respect the past, but also tear down what is useless and non-productive, and replace it with either productive buildings or natural habitat. Your images are well done and show the passion you have for the areas.

Apr 29, 2023 11:56:54 #

OldCADuser wrote:

This is going to be a series of posts covering pla... (show quote)

My company purchased an extrusion machine from Baker Perkins back in the mid-1970s, and it was my job to get it installed and running. We extruded a plastic-like material which was then further processed. It was impressive when it was running!

Bill

Apr 29, 2023 12:21:38 #

billmck wrote:

My company purchased an extrusion machine from Baker Perkins back in the mid-1970s, and it was my job to get it installed and running. We extruded a plastic-like material which was then further processed. It was impressive when it was running!

Did the machine include a pelletizer, which cut-off the extruded material into small pellets? Watching that run was truly amazing as it was done with a large six-bladed, rotating knife, cutting off the extruded material as it came out of the die-plate.

Apr 29, 2023 13:37:33 #

Busbum wrote:

OldCADuser,

Thanks for sharing your images, especially Quincy Mine, I was there in 2016 and have almost the same images as you have posted, very interesting place, did the mine tour and above ground...

Thanks for sharing your images, especially Quincy Mine, I was there in 2016 and have almost the same images as you have posted, very interesting place, did the mine tour and above ground...

As I stated, here are some images taken during the underground mine tour. Note that you don't actually go down the main shaft, but rather through a ventilation 'stoop' on the side of the hill which has been widened out so that you can enter at about the 7th level of the old mine (there were a total of over 90 levels when it was shutdown), which also happens to be just a few feet above where the current water level is now at. When I was going to school there in the late 60's, the mine was only about 2/3 full of water and students used to go down the shaft as far as they able to go, at least down to the 20's levels (note that I never did that as I suffer from acrophobia, and besides, you could be expelled if you were caught). This was before the Park Service took over the site and it was basically abandoned and with little consideration given to making the area safe.

Anyway, to get to the mine tour, you had to first board a tram which took you down the side of the hill, and then you boarded another 'tram' for the ride to the mine opening itself and at least part of the way into the mine. From there, you had to still walk about a quarter mile into the side of the hill, through that expanded 'stoop', until you reached the main shaft.

Here's where you boarded the tram at the top of the hill - October 2010 - Sony DSC-H

And this at the bottom where you leave this tram - October 2010 - Sony DSC-H

And board the second tram that takes you to mine opening and at least part of the way inside - October 2010 - Sony DSC-H

This is what that expanded ventilation 'stoop' looks like as you make your way into the mine - October 2010 - Sony DSC-H

And you eventually reach the main shaft - October 2010 - Sony DSC-H

And here you can see the angle of the strata that the main shaft ran parallel to - October 2010 - Sony DSC-H

These are a couple examples of the air-powered drills which were used to bore holes into the rock face to set explosive charges - October 2010 - Sony DSC-H

And here the guide is showing us one of the drill bits and what one of those rock walls looked like after they had bored a series of charge holes - October 2010 - Sony DSC-H

The guide then turned off all the lights to show what it was like working in the mine with only those acetylene lamps worn by miners or mounted on the walls - October 2010 - Sony DSC-H

This is a typical hand-pushed cart that was used to moved the chunks of ore from the working face of a level to the main shaft where it was taken-up to the surface - October 2010 - Sony DSC-H

If you want to reply, then register here. Registration is free and your account is created instantly, so you can post right away.