for an electrician in UHH Land

Mar 18, 2022 14:20:40 #

I bought a new motor for my belt grinder , for a speed increase, i.e 1725 to 3600 rpm. and hp from 1hp to 1.5hp

Got the swap finished this morning, everything was good until I installed the 2" X72" grinding belt after about 1-2 mins. the thermal switch tripped, I let it cool and reset it tried again checking the temp while running, tripped at 94°f

I am beginning to think the motor is factory wired at 230v and I'm using 115v. QUESTION: IS this possible?

Due to the connection box being so small I can't see the connections, I am not against changing the power cord to 230v.

Got the swap finished this morning, everything was good until I installed the 2" X72" grinding belt after about 1-2 mins. the thermal switch tripped, I let it cool and reset it tried again checking the temp while running, tripped at 94°f

I am beginning to think the motor is factory wired at 230v and I'm using 115v. QUESTION: IS this possible?

Due to the connection box being so small I can't see the connections, I am not against changing the power cord to 230v.

Mar 18, 2022 14:28:37 #

The motor should have a plate on it displaying its operating voltage.

Manglesphoto wrote:

I bought a new motor for my belt grinder , for a s... (show quote)

Mar 18, 2022 14:32:22 #

Manglesphoto wrote:

...Due to the connection box being so small I can't see the connections, I am not against changing the power cord to 230v.

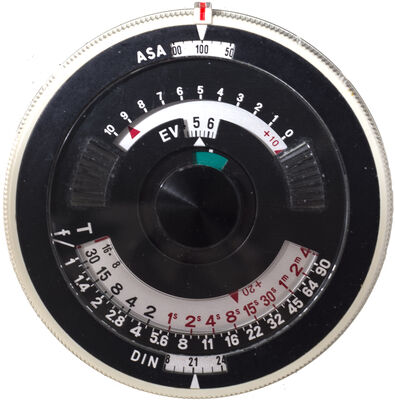

Time to try some macro photography.

Mar 18, 2022 15:35:51 #

anotherview wrote:

The motor should have a plate on it displaying its operating voltage.

Its dual voltage!!!

HOWEVER IT WAS FACTORY WIRED FOR 230V

Problem solved!!!

Mar 18, 2022 15:37:37 #

DirtFarmer wrote:

Time to try some macro photography.

<<<< one track mind sometimes, can't really concentrate on anything else

Problem solved!!!

Mar 18, 2022 18:03:40 #

wingclui44

Loc: CT USA

The HP of this motor is rated at 1.5 and equals to about 1119 watts. at 230v single phrase (general 208-220V from the local utility)so the electric current amp is about 5 amp max. If the voltage switches to 115-120v, the motor will still run, but amp will double that causes to over-load the protecting device to trip.

Stay with 220V!

Stay with 220V!

Mar 18, 2022 20:12:35 #

wingclui44 wrote:

The HP of this motor is rated at 1.5 and equals to about 1119 watts. at 230v single phrase (general 208-220V from the local utility)so the electric current amp is about 5 amp max. If the voltage switches to 115-120v, the motor will still run, but amp will double that causes to over-load the protecting device to trip.

Stay with 220V!

Stay with 220V!

I really don't have a problem with current usage, the problem WAS the the motor was tripping the thermal switch for no apparent reason.

The Problem is solved!!! as far as the 120 vs 240 is not an issue since this is a low usage machine it would have been okay on 120v, it's designed for either and would not have overheated on 120v, However it is much easier to keep it 240v, but not cheaper, a new switch and plug and a few feet of wire.

Mar 19, 2022 05:07:47 #

Yay.

Manglesphoto wrote:

Its dual voltage!!!

HOWEVER IT WAS FACTORY WIRED FOR 230V

Problem solved!!!

HOWEVER IT WAS FACTORY WIRED FOR 230V

Problem solved!!!

Mar 19, 2022 05:41:39 #

Mar 19, 2022 08:34:43 #

I remember rewiring a dual voltage table saw years ago, from 120 to 240, hoping for better performance. Viva la difference!

Mar 19, 2022 13:15:34 #

skipnord

Loc: Corcoran, Minnesota

Or, you could keep the 1750 motor and get a set of 3 step pulleys. Then you could have 3 speeds, which could be a big help - finer belts work better at lower speeds. Or you could always pony up for a variable speed motor and control like mine, but that may be overkill. Regardless of the motor you end up with, I strongly recommend the step pulleys.

From your fellow hog blacksmith.

From your fellow hog blacksmith.

Mar 19, 2022 13:25:57 #

skipnord wrote:

Or, you could keep the 1750 motor and get a set of 3 step pulleys. Then you could have 3 speeds, which could be a big help - finer belts work better at lower speeds. Or you could always pony up for a variable speed motor and control like mine, but that may be overkill. Regardless of the motor you end up with, I strongly recommend the step pulleys.

From your fellow hog blacksmith.

From your fellow hog blacksmith.

I think the fixed 3600rpm motor is fine if that what the OP wants. If I want variable speed I would use a 3 phase motor and VFD.

Mar 19, 2022 13:57:53 #

Manglesphoto, mechanical systems are my area and the manufacturers always set the multi-voltage configurations to the highest voltage selection. They do this because connecting them out-of-the-box to a lower voltage will not fry the motor compared to it being wired for the lowest voltage choice from the factory then being connected to the higher voltage by the user.

We used to say, "motors are made with smoke inside of them and when we let it out they are dead".

We used to say, "motors are made with smoke inside of them and when we let it out they are dead".

Mar 19, 2022 17:49:08 #

skipnord wrote:

Or, you could keep the 1750 motor and get a set of 3 step pulleys. Then you could have 3 speeds, which could be a big help - finer belts work better at lower speeds. Or you could always pony up for a variable speed motor and control like mine, but that may be overkill. Regardless of the motor you end up with, I strongly recommend the step pulleys.

From your fellow hog blacksmith.

From your fellow hog blacksmith.

And what am I going to do with a Step pulley?

The belt grinder is direct drive.

Mar 19, 2022 22:02:22 #

Mozengrazen

Loc: Ilion, NY

Manglesphoto wrote:

I bought a new motor for my belt grinder , for a s... (show quote)

The thermal switch has a coil in it that has to be sized for the current that the new motor draws which should be on the name plate.

If you want to reply, then register here. Registration is free and your account is created instantly, so you can post right away.