Calling all "experienced" photographers

Sep 30, 2018 21:13:53 #

rb61

Loc: Maple Grove, MN

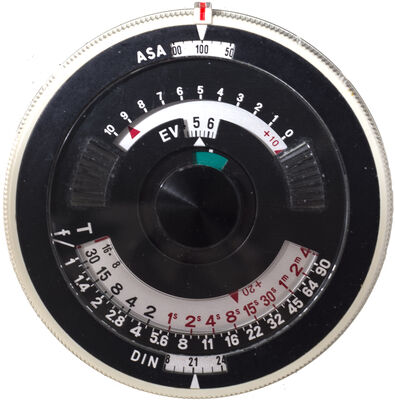

I have a Metz CT-4 flash that has been working well for several decades. Today I find that the ASA dial is frozen.

Any ideas- disassembly instructions, lubrication, etc?

Thanks

Any ideas- disassembly instructions, lubrication, etc?

Thanks

Sep 30, 2018 21:46:17 #

Not familiar with particular unit but assuming it is a mechanical dial first thing I do with frozen items is thaw them! Seriously, by setting it in the sun for awhile that makes all the parts expand a little, especially if has been sitting for a while. Unorthodox but has worked for me.

Sep 30, 2018 22:52:51 #

rb61 wrote:

I have a Metz CT-4 flash that has been working well for several decades. Today I find that the ASA dial is frozen.

Any ideas- disassembly instructions, lubrication, etc?

Thanks

Any ideas- disassembly instructions, lubrication, etc?

Thanks

A German-made hammerhead smart flash!

I take it you mean the film-speed setting knob on the side of the handle?

Unfortunately, I haven't worked on this particular flash. And I don't

have the service manual. But in general:

ASA/ISO knob is probably a multiple throw switch. So if it won't

turn, it's probably jammed on something, or a contact has broken. First,

I'd inspect it from the outside very carefully. If that doesn't reveal

anything, you'll have to disassemble the case.

You probably know that the charged capacitors inside flash units are

high voltage and an electrocution hazard. They are supposed to have

bleeder resistors, but you want to short the caps before poking around

inside, just to make sure.

Open it over a tray, to catch any small pieces that fall out. You're

looking for something that might have gotten jammed in the switch

or broken off from the switch.

Contact cleaner (in a spray can) is the best thing to clean as switches,

IMHO. Common brands include: CRC, MG Chemicals and Radio Shack.

Most are are safe on most plastics, but try a little bit first on a place

where it won't show, just to make sure.

Go slow, take care and stop if you see anything you don't understand.

Sorry I can't be more specific--I hope someone else can. Good luck!

Oct 1, 2018 00:15:39 #

I used to run a service that modified and repair electronic flash gear and have have experience with your unit with this kind of repair. I do not recommend a DIY attempt at disassembly.

There can be a shock hazard even if the unit is turned off and discharged- the capacitors can maintain a residual charge unless they are properly bled out with a wire-wound resistor of the correct value and kept in a shorted state until the repair is completed. The capacitors are in the handle so the disassembly would need to go beyond the lamp housing.

Without disassembly, GENTLY try to loosen the knob at the center of the dial but Do not force anything. Try a bit of electronic cleaning spray- just use the thin nozzle extension to squirt a small amount along side the dial- so it can seep in under it. Give it a few minutes and try to move it again.

If I recall correctly, there is a printed circuit inside the unit at the top of the housing housing- there is a mechanical interface that controls the thyristor function- not easy to reassemble.

If you unit is in good general conditions you can send it to Holly Enterprises.

(800-988-7111) 15848 Rayen Street North Hills, California 91343

They are experts in older flash gear. Give them a call- they are very honest and they will tell you if the repair is worthwhile.

There can be a shock hazard even if the unit is turned off and discharged- the capacitors can maintain a residual charge unless they are properly bled out with a wire-wound resistor of the correct value and kept in a shorted state until the repair is completed. The capacitors are in the handle so the disassembly would need to go beyond the lamp housing.

Without disassembly, GENTLY try to loosen the knob at the center of the dial but Do not force anything. Try a bit of electronic cleaning spray- just use the thin nozzle extension to squirt a small amount along side the dial- so it can seep in under it. Give it a few minutes and try to move it again.

If I recall correctly, there is a printed circuit inside the unit at the top of the housing housing- there is a mechanical interface that controls the thyristor function- not easy to reassemble.

If you unit is in good general conditions you can send it to Holly Enterprises.

(800-988-7111) 15848 Rayen Street North Hills, California 91343

They are experts in older flash gear. Give them a call- they are very honest and they will tell you if the repair is worthwhile.

Oct 1, 2018 00:18:48 #

Oct 1, 2018 00:43:57 #

Hammers? Nah! Some folks called them "potato mashers" back in the day- because of their shape.

Actually, they are pretty decent units- they pack 100 watt-seconds at about 2300 B.C.P.S. Not bad for a one piece unit when you consider the average speedlight is about 80- watt-seconds. Some of the older German units, however, are difficult to repair- they use a lot of printed circuit switches where things slide along contacts at the edge of the circuit board. Tension is provided by little ball bearings tensioned with springs.

Actually, they are pretty decent units- they pack 100 watt-seconds at about 2300 B.C.P.S. Not bad for a one piece unit when you consider the average speedlight is about 80- watt-seconds. Some of the older German units, however, are difficult to repair- they use a lot of printed circuit switches where things slide along contacts at the edge of the circuit board. Tension is provided by little ball bearings tensioned with springs.

Oct 1, 2018 00:49:57 #

E.L.. Shapiro wrote:

I used to run a service that modified and repair e... (show quote)

By all means, send it to his buddies. They gotta eat. Maybe even they'll do a good job for you. But we all know that the labor charges

are going to be more than the flash unit is worth.

Tell me, E. L. Shapiro, how can a discharged capacitor shock someone?

Put a screwdriver across that sucker, make a big spark, and the charge is gone.

Lay the screwdirver across it, just to make sure.

Oct 1, 2018 03:29:57 #

RWR

Loc: La Mesa, CA

rb61 wrote:

I have a Metz CT-4 flash that has been working well for several decades. Today I find that the ASA dial is frozen.

Any ideas- disassembly instructions, lubrication, etc?

Thanks

Any ideas- disassembly instructions, lubrication, etc?

Thanks

Have you checked the position of switch 15 below the “key” symbol?

Oct 1, 2018 05:32:11 #

Pablo8

Loc: Nottingham UK.

Is this the Metz 45 CT-4. Hammer-Head, you are having trouble with? Some posters are referring to "Switches on the side" Nothing like the model that I have. The ASA dial and function (Manual - TTL ) dial is on the top of the head. Batteries (AA's) go into the handle.

Oct 1, 2018 05:47:40 #

The switch 15 is on the 60CT4.

There is no Metz CT4. There is a Metz 45-CT4 and a Metz 60-CT4.

There is no Metz CT4. There is a Metz 45-CT4 and a Metz 60-CT4.

Oct 1, 2018 06:23:27 #

Oct 1, 2018 08:00:03 #

E.L.. Shapiro wrote:

Try a bit of electronic cleaning spray- just use the thin nozzle extension to squirt a small amount along side the dial- so it can seep in under it.

That was my first thought.

Oct 1, 2018 08:41:15 #

Steve DeMott

Loc: St. Louis, Missouri (Oakville area)

Bipod wrote:

By all means, send it to his buddies. They gotta eat. Maybe even they'll do a good job for you. But we all know that the labor charges

are going to be more than the flash unit is worth.

Tell me, E. L. Shapiro, how can a discharged capacitor shock someone?

Put a screwdriver across that sucker, make a big spark, and the charge is gone.

Lay the screwdirver across it, just to make sure.

are going to be more than the flash unit is worth.

Tell me, E. L. Shapiro, how can a discharged capacitor shock someone?

Put a screwdriver across that sucker, make a big spark, and the charge is gone.

Lay the screwdirver across it, just to make sure.

A capacitor can charge with static electricity in the air. If the discharge circuitry has failed a capacitor can/will charge.

I used to work around large modulators with capacitor sizes of 1 to .5 farads and voltages of up to 100,000 volts. These were very dangerous just sitting on the ground. We used 12AWG wire to strap the terminals together.

Oct 1, 2018 09:30:07 #

Bipod wrote:

By all means, send it to his buddies. They gotta eat. Maybe even they'll do a good job for you. But we all know that the labor charges

are going to be more than the flash unit is worth.

Tell me, E. L. Shapiro, how can a discharged capacitor shock someone?

Put a screwdriver across that sucker, make a big spark, and the charge is gone.

Lay the screwdirver across it, just to make sure.

are going to be more than the flash unit is worth.

Tell me, E. L. Shapiro, how can a discharged capacitor shock someone?

Put a screwdriver across that sucker, make a big spark, and the charge is gone.

Lay the screwdirver across it, just to make sure.

First of all- I make a policy of NOT advising anyone to work on high voltage equipment unless the are experienced. If there is even a slight chance that the can be harmed because of my advice, I certainly don't want that to happen. They can also exacerbate the malfunct in the equipment.

OK -You want to talk theory- A capacitor can retain a residual charge or even after is is shorted out unless it is kept in that shorted state during the repair, that is, until the unit needs to be tested before reassembly. There are safety procedures when testing or probing high voltage circuitry- like not using both hands and isolation floor matts.

It is an improper procedure to short out a fully charged capacitor with a screwdriver. That big bang or spark you describe can, in some cases, damage the capacitor or affect or permanently damage other components in the circuit. At least, it can pit, loosen, or burn the terminals on the capacitor and damage the screwdriver. The proper procedure is to place a 500 ohm 25 watt wire-wound resistor across the capacitor(s) and allow it to drain slowly- only take a few minutes and the check, with a voltmeter,to insure there os no voltage present before making repairs. Then a patch cord or jumper wire. shoud be placed across the terminals to prevent a residual charge. The alligator clips and the wires on the patch cords should be fully insulated. Laying something across the terminal is not safe if it is not clipped in place!

Why are you assuming that the shop I recommended are my "buddies"? i have no personal relationships there! I have sent equipmet there, since I closed my repair facility, a number of times and received excellent service. I have recommend them to othere professionals and have had good feedback. In some instances the advised against sending in the gear in that the charges and the shipping would exceed the value of the equipment. You don't maintain a successful business for over 40 years by ripping folks off! Of course there are labor charges- don't you want to be remunerated for your labor. I am sure that the OP is an intelligent adult and can determine whether or not he wishes to invest in his older gear or replace it. There are many of these units still on the used market.

Again, safety, to me, is extremely important. Some electronic flash gear harbor lethal voltages and even the they don't cause deadly electrocution, burns, nerve damage and defibrillation of the heart can result if the shock occurs across the chest. Folks using pacemakers or other implants can be seriously injured or killed.

Lots of folks are reading on, besides the members that join in the conversation. That's why I am careful not to encourage unsafe actions. The folks who know the technology know what to do.

Oct 1, 2018 09:32:57 #

wrangler5

Loc: Missouri

ELNikkor wrote:

a quart of 10W30?

NO NO NO NO NO! Everybody knows you use WD-40 to fix everything. Or is it Windex? (The more experienced I get, the more I disremember.) ;-)

I used a potato masher back in the day - a Sunpak. With a battery pack slung over a shoulder it could keep lighting up family get togethers all night, and I'd rarely have to wait for it to recharge. But once cameras got TTL connectors through the hot shoe, I went to camera-brand flashes on a handle bracket instead (Nikon had a shoe on an extension cord that went on top of the handle.)

If you want to reply, then register here. Registration is free and your account is created instantly, so you can post right away.