How to bore a tapperd hole in a piece of 3/4" thick board.

Feb 26, 2024 08:19:01 #

First drill thru with a smaller bit , then rotate the hand drill around , this would enlarge the hole at one hand . It all depend on how perfect it need to be .

Feb 26, 2024 08:52:26 #

Drill the 1.5" then mark your 2.5 on the other side and use a wood gouge to chisel from the 2.5 mark down to the 1.5 hole.

Feb 26, 2024 09:06:54 #

DirtFarmer wrote:

I would recommend drilling the small hole from the other side rather than the same side as the large bit. A forstner bit will sometimes mess up the wood around the exit of the bit so it's better to have the bit exit within the board in a spot that you are going to file away rather than leave a messy hole on the surface of the board. So you want a pilot hole to mark where the small bit has to start cutting.

you won't mess up an exit hole with a forstner bit if you place a waste piece under\er your work piece !!!

Feb 26, 2024 09:11:45 #

BebuLamar wrote:

I would like to bore a hole in a piece of 1x8" which is 3/4" thick. The hole should be tappered. The large side is 2.5" the smaller side would be 1.5". What is the best way to do this? I have hand drill, jig saw. I don't have good wood working tools.

How accurate does the hole have to be? is the first concern.

Feb 26, 2024 09:16:05 #

Manglesphoto wrote:

How accurate does the hole have to be? is the first concern.

Not very accurate. I want to put this light bulb in and glue it in place and only the dome is sticking out. In fact if you have a better idea I am all for it.

https://www.homedepot.com/p/EcoSmart-100-Watt-Equivalent-R20-CEC-Dimmable-LED-Light-Bulb-in-Daylight-5000K-1-Bulb-A20R2050WT2001/315605717

Feb 26, 2024 09:58:04 #

DaveyDitzer

Loc: Western PA

BebuLamar wrote:

I would like to bore a hole in a piece of 1x8" which is 3/4" thick. The hole should be tappered. The large side is 2.5" the smaller side would be 1.5". What is the best way to do this? I have hand drill, jig saw. I don't have good wood working tools.

After drilling the 1.5" hole use a chamfering bit to start the larger hole and keep it centered.

Feb 26, 2024 10:16:02 #

I would probably cut one hole, just a bit smaller than 2.5". Then use a file to chamfer the top edge of the hole to get the bulb to sit down into the wood just a bit so only the dome is above the surface. Then put the bulb in place, turn it over, and put some caulk/glue/whatever into the hole around the edge to hold the bulb in. You don't have to fit the hole shape to the bulb. And you don't have to fill the space with caulk/glue. You just want to hold it in place.

I assume you have some sort of free-standing socket to get power to the bulb.

I assume you have some sort of free-standing socket to get power to the bulb.

Feb 26, 2024 10:19:40 #

BebuLamar wrote:

Not very accurate. I want to put this light bulb in and glue it in place and only the dome is sticking out. In fact if you have a better idea I am all for it.

https://www.homedepot.com/p/EcoSmart-100-Watt-Equivalent-R20-CEC-Dimmable-LED-Light-Bulb-in-Daylight-5000K-1-Bulb-A20R2050WT2001/315605717

https://www.homedepot.com/p/EcoSmart-100-Watt-Equivalent-R20-CEC-Dimmable-LED-Light-Bulb-in-Daylight-5000K-1-Bulb-A20R2050WT2001/315605717

Hell, just cut a 2.5" 3/4 of the way through then finish with a 1.5" from the back side what the didn't cut should be easy to remove with a pocket knife. or just cut the 2.5" all the way through ,and them add piece of 1/4" plywood with the 1.5" hole using some wood glue

Use hole saws!!!

Feb 27, 2024 23:23:52 #

BebuLamar wrote:

Not very accurate. I want to put this light bulb in and glue it in place and only the dome is sticking out. In fact if you have a better idea I am all for it.

https://www.homedepot.com/p/EcoSmart-100-Watt-Equivalent-R20-CEC-Dimmable-LED-Light-Bulb-in-Daylight-5000K-1-Bulb-A20R2050WT2001/315605717

https://www.homedepot.com/p/EcoSmart-100-Watt-Equivalent-R20-CEC-Dimmable-LED-Light-Bulb-in-Daylight-5000K-1-Bulb-A20R2050WT2001/315605717

How about drilling a simple hole just large enough to clear the neck of the bulb and use the socket to secure it in the hole. Pick a material thickness such when tighten the bulb in the socket, the material just touches the flaring neck of the bulb on one side and the socket on the other, holding it snugly in place.

Feb 29, 2024 04:34:53 #

Feb 29, 2024 08:52:26 #

TriX wrote:

How about drilling a simple hole just large enough to clear the neck of the bulb and use the socket to secure it in the hole. Pick a material thickness such when tighten the bulb in the socket, the material just touches the flaring neck of the bulb on one side and the socket on the other, holding it snugly in place.

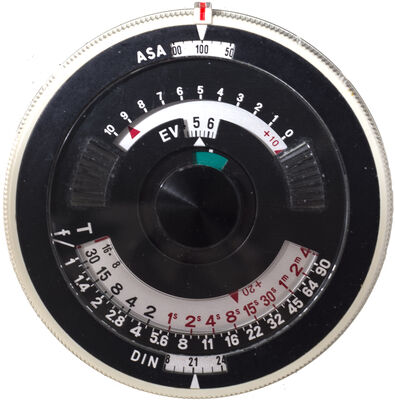

I need the bulb to be almost completely in the wood and only the dome part sticking out. Only the dome part that has light and it's will be inside a diffusion box. I want to put 2 of the bulb at 45 degrees and have the light bouncing off the box walls before the light hit the diffusing plastic sheet at the end. I want to make a 7x7" square surface with very even brightness.

Feb 29, 2024 10:05:26 #

BebuLamar wrote:

I need the bulb to be almost completely in the wood and only the dome part sticking out. Only the dome part that has light and it's will be inside a diffusion box. I want to put 2 of the bulb at 45 degrees and have the light bouncing off the box walls before the light hit the diffusing plastic sheet at the end. I want to make a 7x7" square surface with very even brightness.

You can accomplish that with thicker wood (and a larger hole) so that the neck of the bulb is completely in the wood. But have you looked at the light box Bill Burk built to shoot slides? He has a long ap note on the process describing how he built the illuminating box. How important is the color temp and CRI? Could you use fluorescent tubes? Also, what about surface mount porcelain sockets inside the box and just making it bigger?

Or perhaps something like this (a flat LED plate):

https://www.amazon.com/Ultra-Thin-Adjustable-Brightness-Sketching-Animation/dp/B09NSJTBR4/ref=asc_df_B09NSJTBR4/?tag=hyprod-20&linkCode=df0&hvadid=563721171091&hvpos=&hvnetw=g&hvrand=10414262227477293925&hvpone=&hvptwo=&hvqmt=&hvdev=t&hvdvcmdl=&hvlocint=&hvlocphy=9009733&hvtargid=pla-1646364802726&mcid=778491cbc0093a3a94b4225f6b2c06d1&gclid=Cj0KCQiA84CvBhCaARIsAMkAvkItXu9T8cpNp7cJLzqGjNCkhDXgf1PEcamCljtIlqS0ishC3Tafz_caAhc_EALw_wcB&th=1

Just some thoughts…

Feb 29, 2024 11:42:07 #

TriX wrote:

You can accomplish that with thicker wood (and a l... (show quote)

I found the bulb that I use which has 5000K color temp and I can dim it without making it flickers or change color temp. CRI isn't as important because I do not use it for copying slide or neg. I use it as a light source for testing camera exposure meter.

Mar 1, 2024 11:19:38 #

StanMac

Loc: Tennessee

That tapered bit has a much steeper taper than is needed. I think drilling a through hole and using a coping saw and working it to the outlines of the top and bottom of the taper to get the it at the right angle then working it around the circle will give a cleaner hole.

Stan

Stan

If you want to reply, then register here. Registration is free and your account is created instantly, so you can post right away.