How do I attach a disk to a motor

Feb 16, 2024 07:25:04 #

I have a small motor which has a 0.2" diameter shaft. I want to attach a disk about 5-6"in diameter. The disk would in plastic. What is an in expensive way to do this?

Feb 16, 2024 07:39:19 #

BebuLamar wrote:

I have a small motor which has a 0.2" diameter shaft. I want to attach a disk about 5-6"in diameter. The disk would in plastic. What is an in expensive way to do this?

I'll make a guess there is no threaded end on the shaft.

A collar with a set screw locker? ......if you can find a way to attach the disc to the collar.

The specialty fastener drawers at Lowe's probably have some different sizes of plastic collars. It may be possible to drill and tap a hole for a set screw, in an appropriate plastic collar, if that would make it easier to fasten collar and disc together.

Feb 16, 2024 07:40:52 #

dustie wrote:

I'll make a guess there is no threaded end on the shaft.

A collar with a set screw locker? ......if you can find a way to attach the disc to the collar.

The specialty fastener drawers at Lowe's probably have some different sizes of plastic collars. It may be possible to drill and tap a hole for a set screw, in an appropriate plastic collar, if that would make it easier to fasten collar and disc together.

A collar with a set screw locker? ......if you can find a way to attach the disc to the collar.

The specialty fastener drawers at Lowe's probably have some different sizes of plastic collars. It may be possible to drill and tap a hole for a set screw, in an appropriate plastic collar, if that would make it easier to fasten collar and disc together.

Yes the shaft is not threaded. It does have a flat spot that you can use a set screw.

Feb 16, 2024 07:45:25 #

BebuLamar wrote:

Yes the shaft is not threaded. It does have a flat spot that you can use a set screw.

How much force will be applied against the disc when it's in use?

Feb 16, 2024 07:50:28 #

dustie wrote:

How much force will be applied against the disc when it's in use?

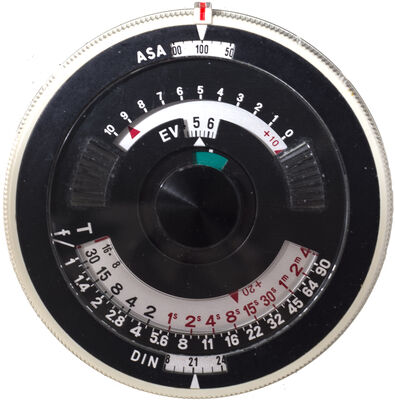

just to spin the disk so it's not much force. I would accelerate it slowly so there won't be a lot of force involved. I would draw a line on the disk and spin it at certain speed (the motor I have can be made to spin at very accurate speed) and take a picture and see the motion blur to figure out the shutter speed of the digital camera.

Feb 16, 2024 07:51:24 #

dustie wrote:

I'll make a guess there is no threaded end on the shaft.

A collar with a set screw locker? ......if you can find a way to attach the disc to the collar.

The specialty fastener drawers at Lowe's probably have some different sizes of plastic collars. It may be possible to drill and tap a hole for a set screw, in an appropriate plastic collar, if that would make it easier to fasten collar and disc together.

A collar with a set screw locker? ......if you can find a way to attach the disc to the collar.

The specialty fastener drawers at Lowe's probably have some different sizes of plastic collars. It may be possible to drill and tap a hole for a set screw, in an appropriate plastic collar, if that would make it easier to fasten collar and disc together.

Feb 16, 2024 07:58:10 #

BebuLamar wrote:

just to spin the disk so it's not much force. I would accelerate it slowly so there won't be a lot of force involved. I would draw a line on the disk and spin it at certain speed (the motor I have can be made to spin at very accurate speed) and take a picture and see the motion blur to figure out the shutter speed of the digital camera.

A suitable adhesive may be able to attach a collar to the disc for that, providing you can come up with materials that are compatible with the adhesive formula.

Feb 16, 2024 09:23:20 #

BebuLamar wrote:

I have a small motor which has a 0.2" diameter shaft. I want to attach a disk about 5-6"in diameter. The disk would in plastic. What is an in expensive way to do this?

.2 is a odd size, are you sure that it's not MM shaft?

Feb 16, 2024 09:26:50 #

Feb 16, 2024 10:02:21 #

If you have access to making the parts (or maybe there's something available on McMaster - there usually is) you could consider locking the wheel in place with a sleeve either side, each sleeve having a locking grub screw. The sleeves (or flanges) would be mounted such that the grub screws are 180° from each other.

Feb 16, 2024 11:39:47 #

Feb 16, 2024 11:58:51 #

As long as the shaft isn't too smooth and there wasn't too much friction acting against the wheel causing acceleration between shaft and wheel, epoxy would probably work.

An entire 20 seconds of research went into finding these... https://www.mcmaster.com/products/retainers/shaft-collars-2~/system-of-measurement~metric/shaft-diameter~5-mm/

or something similar to these: https://www.mcmaster.com/products/retaining-rings/push-on-retaining-caps-6/

An entire 20 seconds of research went into finding these... https://www.mcmaster.com/products/retainers/shaft-collars-2~/system-of-measurement~metric/shaft-diameter~5-mm/

or something similar to these: https://www.mcmaster.com/products/retaining-rings/push-on-retaining-caps-6/

Feb 16, 2024 13:30:39 #

Feb 16, 2024 15:29:28 #

Warhorse

Loc: SE Michigan

kenJN wrote:

buy a disk attachment for a power sander or drill. Ace Hdw is the place.

Feb 16, 2024 16:13:10 #

Thanks all. Attachment for power sander or drill wouldn't work because the sander or drill has a chuck. This motor only has a shaft.

If you want to reply, then register here. Registration is free and your account is created instantly, so you can post right away.