The reason I hated the 1964/65 Mustang

Dec 16, 2022 14:42:25 #

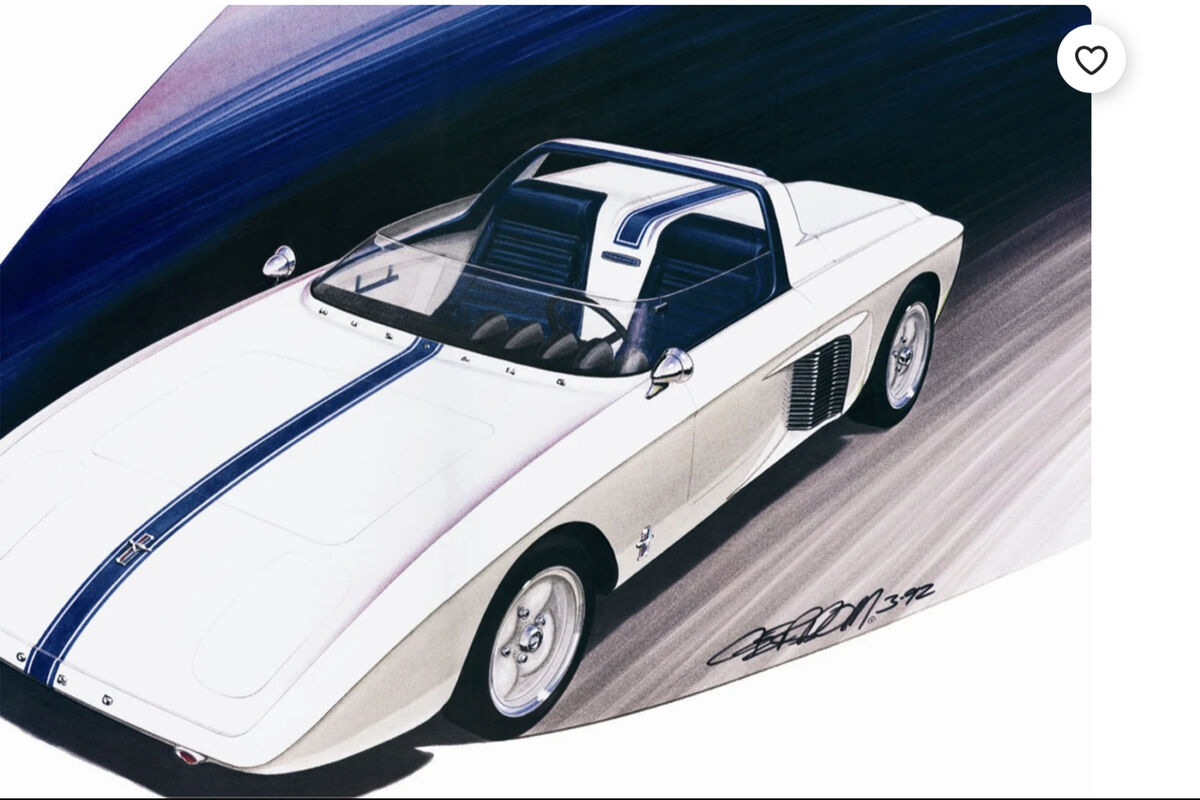

This is the 1962 Mustang I, that never when into production.

I fell in love with this concept car when I saw it in Popular Mechanics Mag.

When the Mustang hit the show rooms in 1964 I thought it was the ugliest thing I ever saw, I didn't like the Mustangs until the Fastback came out.

I fell in love with this concept car when I saw it in Popular Mechanics Mag.

When the Mustang hit the show rooms in 1964 I thought it was the ugliest thing I ever saw, I didn't like the Mustangs until the Fastback came out.

Dec 16, 2022 14:50:09 #

Klickitatdave

Loc: Seattle Washington

It is too bad that the 1962 Mustang concept car devolved into the 1964 non fastback model. The concept Mustang is definitely a "boss" car.

Dec 16, 2022 14:58:08 #

The 64 Mustang was all the rave when it came out. The first Mustang rolled off the assembly line March 9, 1964, and it made its national debut on April 17th. With a list price of $2,368, by the weekend, 22,000 cars were ordered and some 303,408 were built that first year. My first Mustang was a 1968. I traded it for a 1969 yellow fastback with a 302ci engine. It is the only car I wish I had kept.

Dec 16, 2022 15:36:02 #

Dec 16, 2022 16:06:21 #

I had a "64 1/2" white Mustang convertible, purchased second hand in 67 or 68 from a second lieutenant who was headed to Vietnam. Car was ruined in Hurricane Camille when a eight-inch diameter tree branch came through the roof and the car filled almost to the bottom of the window. Was able to sell it to someone and purchased the new Ford Maverick.... ah, those were the days....

Dec 16, 2022 19:00:29 #

Dec 16, 2022 22:45:32 #

bikinkawboy

Loc: north central Missouri

Mustangs looked good and sold really well, but they were rust magnets. With the uni body design, the body then sagged, doors hung up or wouldn’t close, spring hangers poked through the trunk floor and so on. After making millions of them, that’s one reason there are so relatively few left. Fortunately you can buy reproduction body panels and patch kits. That is the reason you see as many as you do these days.

Funny how time makes one forget all the bad things about a car you once had but then dolls up the good times you had, making you reminisce it as being so wonderful. Look at it this way, if it was so great, why did you willingly get rid of it? Because it was a worn out heap slowly rusting down into a pile of rust.

Funny how time makes one forget all the bad things about a car you once had but then dolls up the good times you had, making you reminisce it as being so wonderful. Look at it this way, if it was so great, why did you willingly get rid of it? Because it was a worn out heap slowly rusting down into a pile of rust.

Dec 16, 2022 23:23:37 #

Until Don Petersen became CEO in the early 80's. The design committee had a nasty habit of "straightening out" the curves. On clay models, they would literally take large knives and remove the sweep of fenders and roof-lines to create boxier looking vehicles, which they believed would sell better against GM. I've seen some of the late 70's mock-ups, and the original designs of the Crown Vic/Grand Marquis were quite aerodynamic, but the design committee nixed the sleeker concept.

In model year 1983, the T-bird got "aeroed". From then on, all vehicles lost their edges and went aero, since that's what wind-tunnel testing was telling them anyway. The 1986 Taurus/Sable was designed and run through the wind tunnel from the get go.

A bit later on, Roger Smith, CEO of GM, commented on how the Taurus/Sable reminded him of a "turtle". Don Petersen retorted that "Roger Smith wishes he had some of those 'turtles' to sell." Taurus/Sable owned the class.

In model year 1983, the T-bird got "aeroed". From then on, all vehicles lost their edges and went aero, since that's what wind-tunnel testing was telling them anyway. The 1986 Taurus/Sable was designed and run through the wind tunnel from the get go.

A bit later on, Roger Smith, CEO of GM, commented on how the Taurus/Sable reminded him of a "turtle". Don Petersen retorted that "Roger Smith wishes he had some of those 'turtles' to sell." Taurus/Sable owned the class.

Dec 17, 2022 08:36:56 #

Dec 17, 2022 08:39:13 #

With all due respect if Ford made the Mustang that looks like the one in the picture it wouldn't be a sucess like it was.

Dec 17, 2022 09:03:28 #

pendennis wrote:

Until Don Petersen became CEO in the early 80's. ... (show quote)

Most of the big, ugly decisions were made at Henry Ford’s desk. He hated the success Iacocca was having so he vetoed much of his plans. The Board clipped back Henry’s wings a bit when others were hired to get Ford back in the picture. The Taurus, which looked like a football, was a huge success and a best seller for years. The once popular Explorer is now one of the worst rated SUV’s by automobile rating organizations due to quality issues. I used to be a huge Ford fan and owner until I started to have to deal with their poor quality.

Dec 17, 2022 09:28:44 #

Dec 17, 2022 09:35:30 #

StanMac

Loc: Tennessee

Klickitatdave wrote:

It is too bad that the 1962 Mustang concept car devolved into the 1964 non fastback model. The concept Mustang is definitely a "boss" car.

So many beautiful “concept” cars never make or made it into production, which makes no sense to me. Those that were well received with oooohhhhss and aaaahhhhs by the public get so watered down in the production model their desirability gets tanked. While the Mustang was a big hit even with its watered down styling, it would have been even more of one in the original concept, IMO.

Stan

Dec 17, 2022 09:59:13 #

Kmgw9v wrote:

I wish I had kept my red 66 Mustang with the 289; but I didn’t.

I had a ‘66 2+2 fastback in blue with the 289. Also, a ‘68 convertible in green. I don’t regret selling them since I bought a BRG ‘69 Jag XKE roadster that I do regret selling.

Dec 17, 2022 10:06:51 #

StanMac wrote:

So many beautiful “concept” cars never make or made it into production, which makes no sense to me. Those that were well received with oooohhhhss and aaaahhhhs by the public get so watered down in the production model their desirability gets tanked. While the Mustang was a big hit even with its watered down styling, it would have been even more of one in the original concept, IMO.

Stan

Stan

There's often a fine line between what is conceptual and what the carmaker can build. At Ford, part of the problem, as with all automakers, is the ability to get sheet metal from the concept to the stamping press. Sheet metal has a "memory", and you can only stress it so much during production. Even with multiple strikings along several presses, it's still difficult to achieve a design sometimes. And during the period before CAD/CAM, all of the dies were machined pretty much by "guess", not that micromatic tools weren't utilized. Before lasers came along, the best test of sheet metal finish, was the operator using a gloved hand to feel for any imperfections. Later on, when vehicles also got non-metal body parts such as hoods and deck lids, it became much easier to hold metal specs.

There was also the problem of body fixtures at the assembly plant. We used body bucks to hold sheet metal in position, and then an operator would make a number of welds attempting to hold a spec. If the spec was .5", the operator could hold "fairly" close to that tolerance, but there wasn't always a guaranteed hit. Until the robotic welders came along in the late 70's, "close" was what you got. We also had "blue bucks", which were the original specified body bucks, and sheet metal was periodically pulled off line and inserted in the blue buck to confirm specs. When we started using robotic welders, a lot of those problems went away.

Before design changes, pretty much all vehicles went through soldering processes. Even with the best available ventilation systems, you could still smell some lead solder fumes in the body shops. Then the bodies were sanded along those joints before going to the paint department.

There was also the barrier wall between the line operators and the process and production engineers. If the engineer believed the operator was in error, then it was the operator's fault. When our plant was assigned the Ford Ranger production, the old methods were tossed out, and we sent operators by the dozens to our pilot plant in Allen Park, Michigan to learn the best methods of production, and the operators' comments and suggestions were fully implemented in parts design and process. Brake and electrical lines were no longer rigidly affixed to the body and chassis. When line speeds were moved from 40 +/- jobs per hour, to 80 JPH, production had to be simplified.

If you want to reply, then register here. Registration is free and your account is created instantly, so you can post right away.