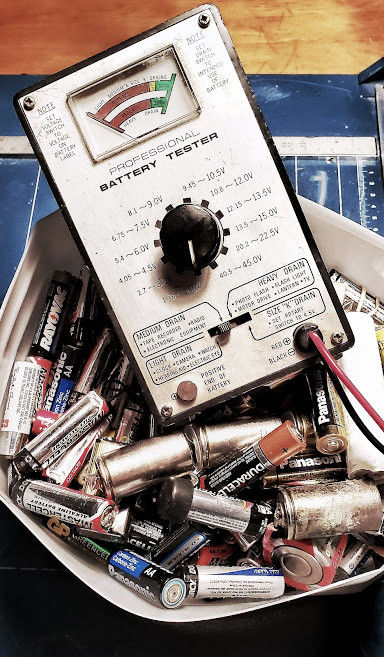

Battery Checker

Nov 24, 2020 09:01:51 #

tca2267

Loc: Florida

Does anyone know if there is a battery checker to check the batteries [ EN-EL15 EN-EL15a ]

used in the Nikon D7200...D750....D500 and d850....

used in the Nikon D7200...D750....D500 and d850....

Nov 24, 2020 09:11:41 #

This might help.

https://electronics.stackexchange.com/questions/18612/how-to-measure-capacity-of-a-lithium-ion-battery/18613#18613

Connecting a multimeter will tell you what's going on inside.

https://electronics.stackexchange.com/questions/18612/how-to-measure-capacity-of-a-lithium-ion-battery/18613#18613

Connecting a multimeter will tell you what's going on inside.

Nov 24, 2020 09:37:26 #

Just slip them into the camera - it will tell all, and it just takes a moment. I use a rubber band to I.D charged vs discharged.

Nov 24, 2020 10:09:03 #

quixdraw wrote:

I use a rubber band to I.D charged vs discharged.

That’s a good idea.

Nov 24, 2020 10:18:34 #

quixdraw wrote:

Just slip them into the camera - it will tell all, and it just takes a moment.

You beat me to it.

You beat me to it.Nov 24, 2020 10:27:27 #

Nov 24, 2020 10:36:13 #

larryepage

Loc: North Texas area

tca2267 wrote:

Does anyone know if there is a battery checker to check the batteries [ EN-EL15 EN-EL15a ]

used in the Nikon D7200...D750....D500 and d850....

used in the Nikon D7200...D750....D500 and d850....

The problem is that with the latest technology batteries, there is no way for you or a battery checker to make a connection with the battery itself...only with the output terminals of the control circuit that manages that battery and protects it (and you) from damage and injury. If you don't have the "secret code" that controls that circuitry, about all you can do is measure the output voltage that it is providing.

You may be able to see minor changes in output voltage to determine whether the battery is charged or not, but probing around the output terminals of a battery can be dangerous, even with their protective circuits. Accidentally connecting a multimeter that is set to measure current could be dangerous to the meter, the battery, and to you. There is an incredible amount of energy stored in a lithium ion battery, and the heat generated by a short circuit can release a lot of it in a very short time.

As has been stated, the battery meter in the camera is your best bet. Even the techniques described in the article using the charger indicator can give misleading resultd, especially with third party batteries that may not provide proper charge indication.

Nov 24, 2020 17:17:13 #

jdubu

Loc: San Jose, CA

quixdraw wrote:

Just slip them into the camera - it will tell all, and it just takes a moment. I use a rubber band to I.D charged vs discharged.

A simple way to mark the batteries you have.

Currently, I put a small red sticker on one side of the battery bottom where the cover goes on. The covers have a small hole on one side so when the battery is charged, I put the cover on so the red sticker is not visible. Drained, the cover hole goes over the red sticker indicating it is dead.

I like yours, I could just rubber band the cover to the battery to indicate it is dead.

Nov 24, 2020 23:22:27 #

tca2267 wrote:

Does anyone know if there is a battery checker to check the batteries [ EN-EL15 EN-EL15a ]

used in the Nikon D7200...D750....D500 and d850....

used in the Nikon D7200...D750....D500 and d850....

What quixdraw and joer said. All of the cameras you mentioned have the ability to give the % of charge left.

Nov 25, 2020 12:56:58 #

Kozan

Loc: Trenton Tennessee

jerryc41 wrote:

This might help.

https://electronics.stackexchange.com/questions/18612/how-to-measure-capacity-of-a-lithium-ion-battery/18613#18613

Connecting a multimeter will tell you what's going on inside.

https://electronics.stackexchange.com/questions/18612/how-to-measure-capacity-of-a-lithium-ion-battery/18613#18613

Connecting a multimeter will tell you what's going on inside.

You really have to check batteries under a load. Usually with a 1K resistor. Batteries can have the full-charge voltage but are not able to produce the proper current.

Nov 25, 2020 15:54:01 #

Even if you could access the terminal on your camera battery, or any battery for that matter, a proper tester will only indicate if there's sufficient voltage under load at the time of testing. It usually can not indicate the degree of remaining charge, how many more discharge/recharge cycles are left before the battery is no longer viable. Some of the latest battery technologies have very different charismatics than their predecessors.

If your camera has the internal circuitry to monitor your batteries, that is your best bet, however, any battery, regardless of make, model, type, OEM or a third party, and even brand new out of the box can unceremoniously fail or drop dead at the most inopportune times. Always keep sufficient spares on hand and keep track of age and charging cycles.

As I have posted many times, today's cameras are entirely dependent on electronics- not only the meter or the motor drove, but the entire system and there is no single mechanical shutter speed that will function when the battery is down. Gone are the days wehn you could stop off at just about any handy store and buy a bunch of Coppertops, Energizers, or button batters and fire up a dead camera.

If your camera has the internal circuitry to monitor your batteries, that is your best bet, however, any battery, regardless of make, model, type, OEM or a third party, and even brand new out of the box can unceremoniously fail or drop dead at the most inopportune times. Always keep sufficient spares on hand and keep track of age and charging cycles.

As I have posted many times, today's cameras are entirely dependent on electronics- not only the meter or the motor drove, but the entire system and there is no single mechanical shutter speed that will function when the battery is down. Gone are the days wehn you could stop off at just about any handy store and buy a bunch of Coppertops, Energizers, or button batters and fire up a dead camera.

Nov 25, 2020 17:58:55 #

Nov 25, 2020 18:15:21 #

larryepage wrote:

The problem is that with the latest technology bat... (show quote)

Right on, Larry.

Thanks

W6BEB

Nov 25, 2020 19:50:10 #

This from Underwriters Laboratories (UL)

Electrical Tests

• External Short Circuit Test — The

external short circuit test creates

a direct connection between the

anode and cathode terminals of

a cell to determine its ability to

withstand a maximum current

flow condition without causing

an explosion or fire

• Abnormal Charging or Overcharging

Test — The abnormal charging

test applies an over-charging

current rate and charging time to

determine whether a sample can

withstand the condition without

causing an explosion or fire. The

overcharge test attempts to

charge a battery to greater than

100% state of charge through

various methods

• Forced Discharge or Overdischarge

Test — The forced discharge test

determines a battery’s behavior

when a discharged cell is connected

in series with a specified number

of charged cells of the same type.

The goal is to create an imbalanced

series connected pack, which is

then short-circuited. To pass this

test, no sample cell may explode

or catch fire. The overdischarge

attempts to continue discharging

beyond the specified of the

discharge limit

Mechanical Tests

• Crush Test — The crush test

determines a cell’s ability to

withstand a specified crushing

force (typically 13 kN) applied by

two flat plates (typically although

some crush methods such as SAE

J2929 include a steel rod crush

for cells and ribbed platen for

batteries). To pass this test, a

sample may not explode or ignite.

There are additional criteria for

high voltage or large batteries

such as those used in electric

vehicle applications

• Impact Test (cell) — The impact

test determines a cell’s ability

to withstand a specified impact

applied to a cylindrical steel rod

placed across the cell under test.

To pass this test, a sample

may not explode or ignite

• Shock Test — The shock test is

conducting by securing a cell or

battery under test to a testing

machine that has been calibrated

to apply a specified average and

peak acceleration for the specified

duration of the test. To pass this

test, a sample may not explode,

ignite, leak or vent

• Vibration Test — The vibration

test applies a simple harmonic

motion at a specified amplitude,

with variable frequency and time

to each sample. To pass this test, a

sample may not explode, ignite,

leak or vent

• Drop Test — The drop test subjects

each cell and/or battery sample

to a specified number of free falls

to a hard surface. The sample is

examined after a time following

each drop. To pass this test, a

sample may not explode or ignite.

There are additional criteria for

high voltage or large batteries

such as those used in electric

vehicle applications

Environmental Tests

• Heating Test — The heating

test evaluates a cell’s ability to

withstand a specified application

of an elevated temperature for

a period of time. To pass this test,

a sample may not explode or ignite

• Temperature Cycling Test —

The temperature cycling test

subjects each sample to specified

temperature excursions above

and below room temperature

for a specified number of cycles.

To pass this test, a sample may

not explode, ignite, vent or leak.

There are additional criteria for

high voltage or large batteries such

as those used in electric vehicle

applications

• Low Pressure (altitude) Test —

The low-pressure test evaluates a

sample for its ability to withstand

exposure to less than standard

atmospheric pressure (such as

might be experienced in an aircraft

cabin that experiences sudden

loss of pressure). To pass this test,

a sample may not explode, ignite,

vent or leak

Additional Specialized Tests

In addition to the common abuse tests

discussed above, certain product safety

standards and testing protocols for

lithium-ion batteries require additional

specialized testing. These specialized

tests address exposure to an external

or internal fire and material/insulation

integrity evaluations.

• Projectile (fire) or Internal Fire Test

— The projectile test subjects a

cell sample to a flame from a test

Safety Issues for Lithium-Ion Batt

Lots of talk about explosion and fire! Of course, this may pertin more to automotive and aircraft applications and other heavy industrial usages of lithium-ion batteries, as opposed to relatively lower voltage camera batteries, nonetheless, I wouldn't advise poking around with a screwdriver or a test lead unless you know exactly what you are doing.

Electrical Tests

• External Short Circuit Test — The

external short circuit test creates

a direct connection between the

anode and cathode terminals of

a cell to determine its ability to

withstand a maximum current

flow condition without causing

an explosion or fire

• Abnormal Charging or Overcharging

Test — The abnormal charging

test applies an over-charging

current rate and charging time to

determine whether a sample can

withstand the condition without

causing an explosion or fire. The

overcharge test attempts to

charge a battery to greater than

100% state of charge through

various methods

• Forced Discharge or Overdischarge

Test — The forced discharge test

determines a battery’s behavior

when a discharged cell is connected

in series with a specified number

of charged cells of the same type.

The goal is to create an imbalanced

series connected pack, which is

then short-circuited. To pass this

test, no sample cell may explode

or catch fire. The overdischarge

attempts to continue discharging

beyond the specified of the

discharge limit

Mechanical Tests

• Crush Test — The crush test

determines a cell’s ability to

withstand a specified crushing

force (typically 13 kN) applied by

two flat plates (typically although

some crush methods such as SAE

J2929 include a steel rod crush

for cells and ribbed platen for

batteries). To pass this test, a

sample may not explode or ignite.

There are additional criteria for

high voltage or large batteries

such as those used in electric

vehicle applications

• Impact Test (cell) — The impact

test determines a cell’s ability

to withstand a specified impact

applied to a cylindrical steel rod

placed across the cell under test.

To pass this test, a sample

may not explode or ignite

• Shock Test — The shock test is

conducting by securing a cell or

battery under test to a testing

machine that has been calibrated

to apply a specified average and

peak acceleration for the specified

duration of the test. To pass this

test, a sample may not explode,

ignite, leak or vent

• Vibration Test — The vibration

test applies a simple harmonic

motion at a specified amplitude,

with variable frequency and time

to each sample. To pass this test, a

sample may not explode, ignite,

leak or vent

• Drop Test — The drop test subjects

each cell and/or battery sample

to a specified number of free falls

to a hard surface. The sample is

examined after a time following

each drop. To pass this test, a

sample may not explode or ignite.

There are additional criteria for

high voltage or large batteries

such as those used in electric

vehicle applications

Environmental Tests

• Heating Test — The heating

test evaluates a cell’s ability to

withstand a specified application

of an elevated temperature for

a period of time. To pass this test,

a sample may not explode or ignite

• Temperature Cycling Test —

The temperature cycling test

subjects each sample to specified

temperature excursions above

and below room temperature

for a specified number of cycles.

To pass this test, a sample may

not explode, ignite, vent or leak.

There are additional criteria for

high voltage or large batteries such

as those used in electric vehicle

applications

• Low Pressure (altitude) Test —

The low-pressure test evaluates a

sample for its ability to withstand

exposure to less than standard

atmospheric pressure (such as

might be experienced in an aircraft

cabin that experiences sudden

loss of pressure). To pass this test,

a sample may not explode, ignite,

vent or leak

Additional Specialized Tests

In addition to the common abuse tests

discussed above, certain product safety

standards and testing protocols for

lithium-ion batteries require additional

specialized testing. These specialized

tests address exposure to an external

or internal fire and material/insulation

integrity evaluations.

• Projectile (fire) or Internal Fire Test

— The projectile test subjects a

cell sample to a flame from a test

Safety Issues for Lithium-Ion Batt

Lots of talk about explosion and fire! Of course, this may pertin more to automotive and aircraft applications and other heavy industrial usages of lithium-ion batteries, as opposed to relatively lower voltage camera batteries, nonetheless, I wouldn't advise poking around with a screwdriver or a test lead unless you know exactly what you are doing.

Nov 25, 2020 20:07:00 #

larryepage wrote:

The problem is that with the latest technology batteries, there is no way for you or a battery checker to make a connection with the battery itself...

...and a lot of battery doom follows...

It's not that hard. If your average lithium battery is fully charged, it will read 8.4 volts. If it is discharged, it will read around 7 volts. Fully discharged, 6 volts and hopefully not less. If it doesn't last as long as it used to, it's probably bad.

Not everybody has (or needs!) a Cadex 7000 series analyzer...

If you want to reply, then register here. Registration is free and your account is created instantly, so you can post right away.